If just for testing purposes, then sure, some of them could be bypassed with a jumper wire in order to get the signal down at VH below 5VDC.

But not for a long term solution.

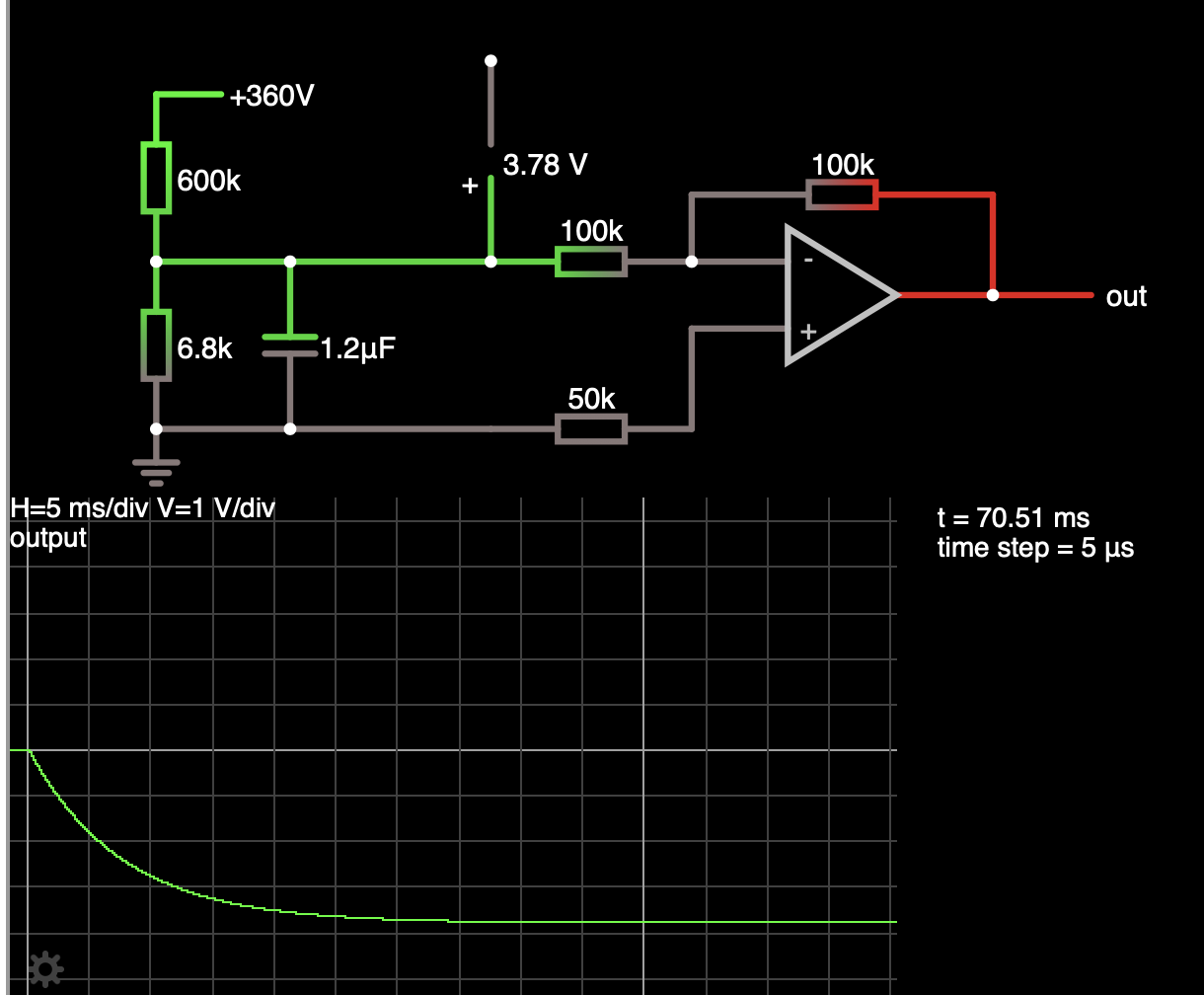

Here's an idea to test while you are waiting for parts: if you have an extra AD8677 op amp, wire one up by itself on the bench in a bread board or dead bug wire it, with +5 and -5 supplies, then apply input on pin 2 with pin 3 grounded; apply 3, 3.5, 4 volts thru a resistor to pin 2 and observe if it gets pulled back down to 3.5 when the input is higher than that. If you don't have enough power supplies, just use +5 and return for supplies since you are only testing the input with a positive signal if should still bleed off the excess.

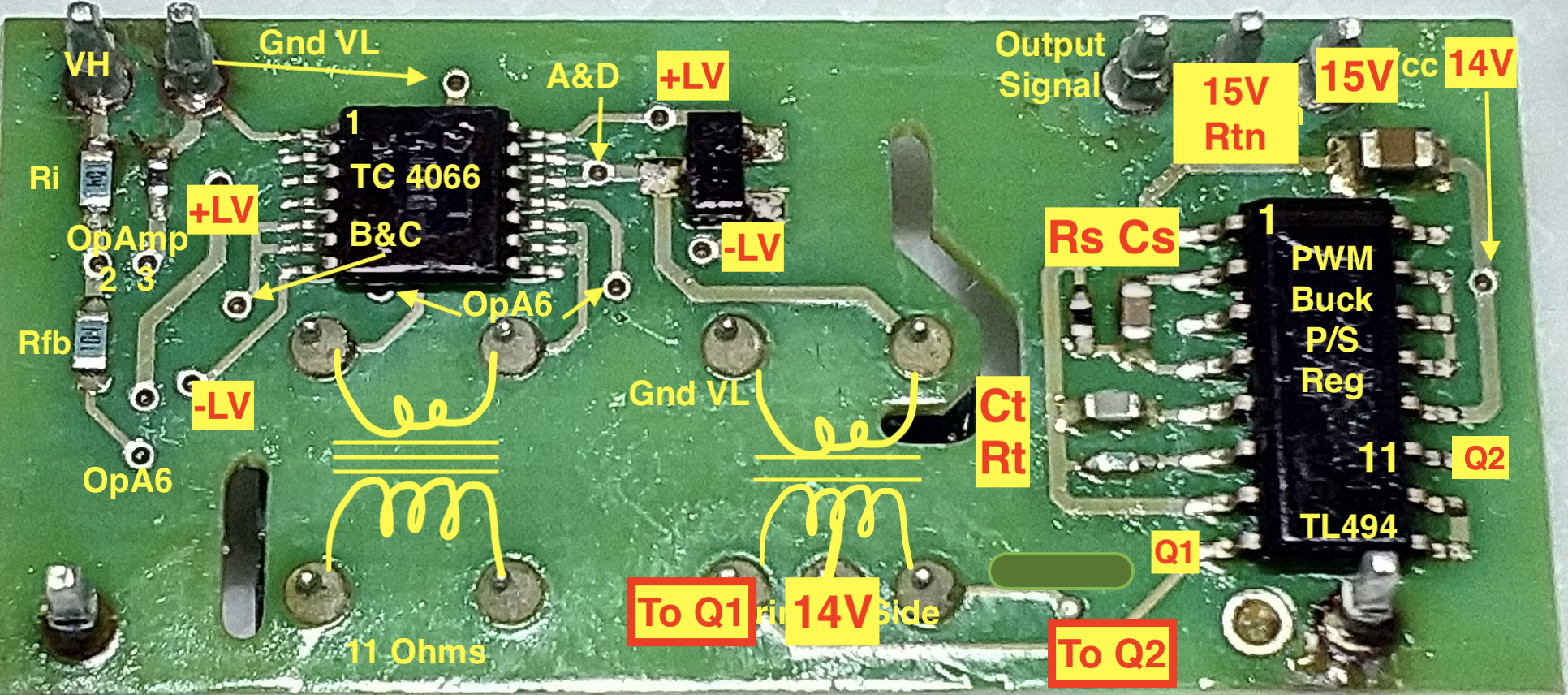

i was quite surprised to see all the hidden vias under the PWM chip.

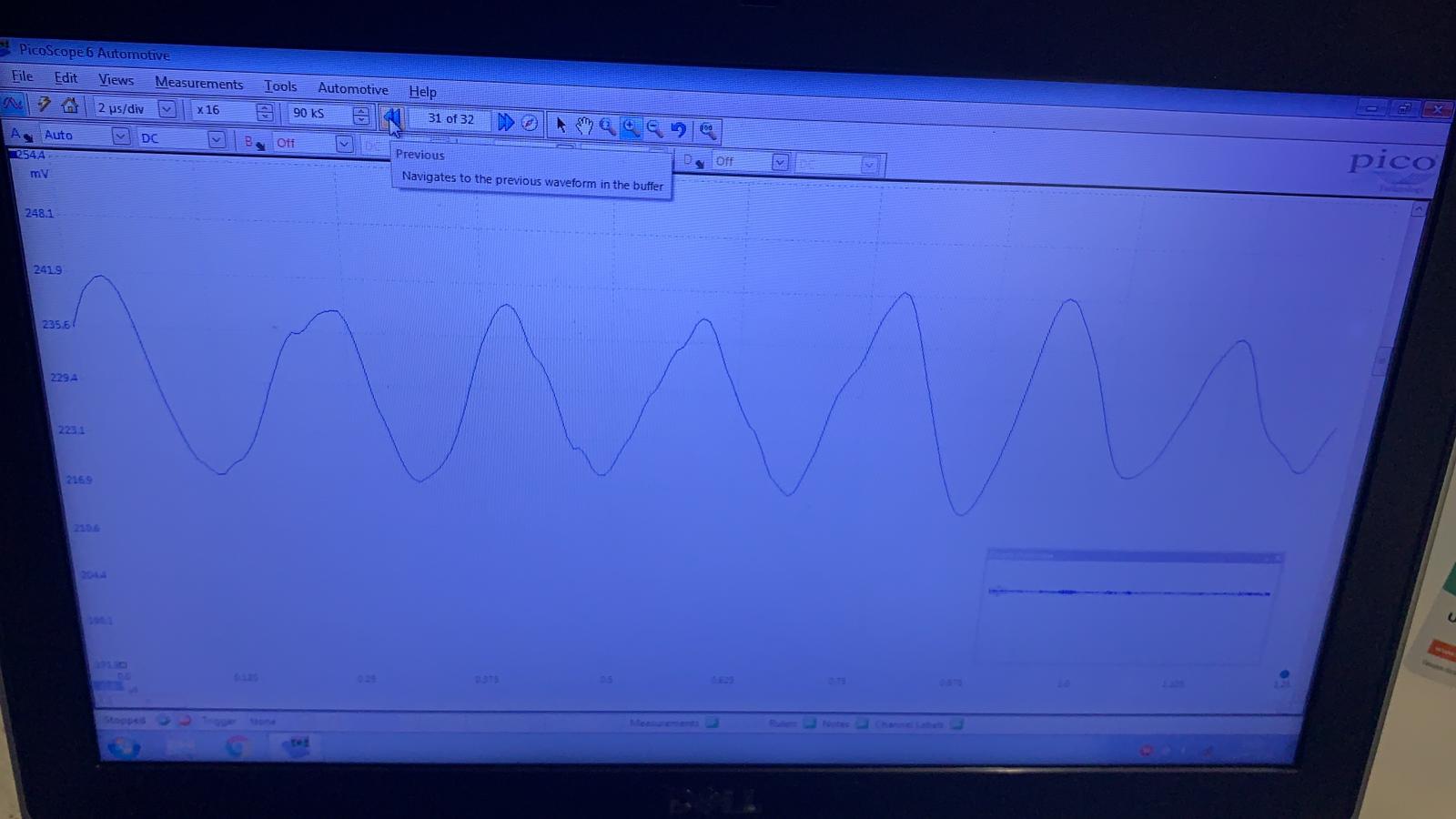

The hash in the + and - supplies is occurring at 50 and 100 Hz, so i suspect that noise is from the mains frequency, the burst width is about 6msec.

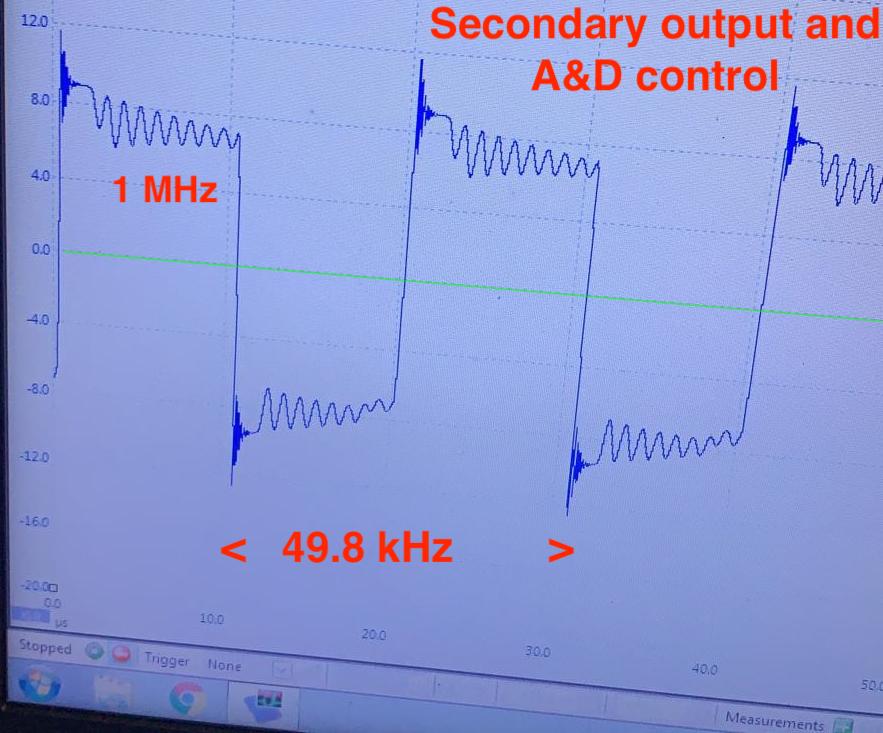

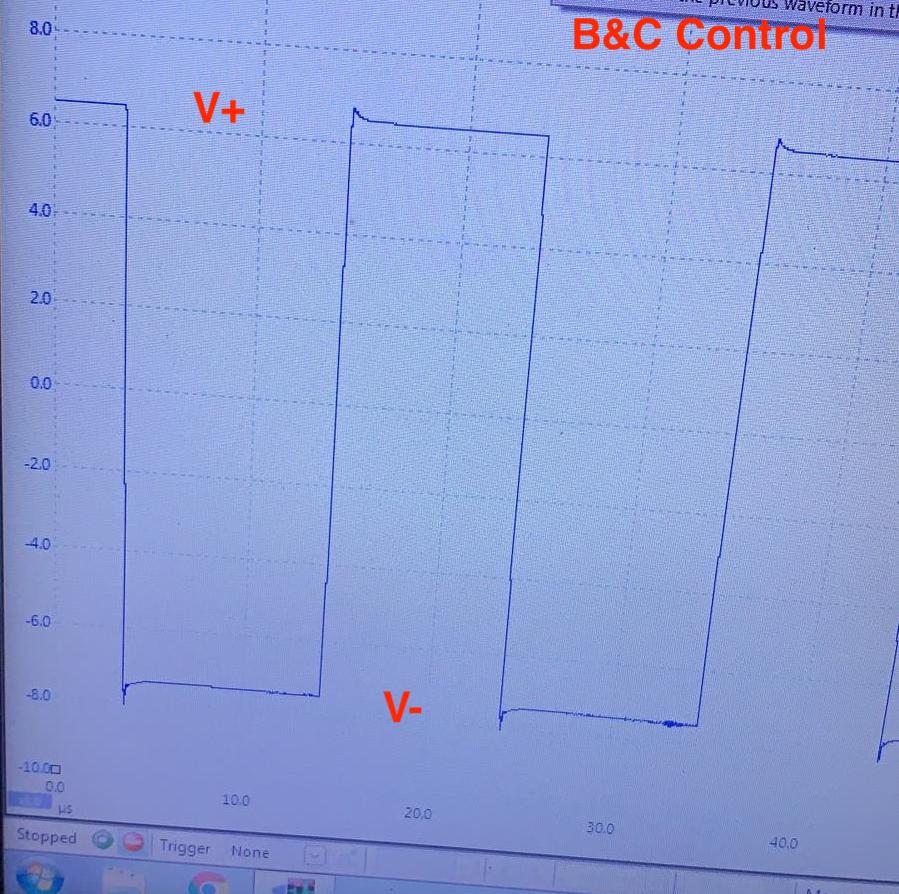

The switch control lines AD and BC are at about 53kHz, which is the expected frequency from the PWM chip, so the little resistor and capacitor on TL494 pins 5 and 6 are doing their job. The waveform appears symmetric so the deadtime control is not out of whack.

Just looking at the small band about the mean it would seem the ripple is about 130mV.

If the op amp output on pin 6 is the inverted equal to the input on VH, then it is likely working okay and no need to disturb or swap it out--the problem seems to be downstream of there, such as the 4066, or the signal transformer, or the output 4066 and LPF.

There are no easy access vias for test points for the other end, but that all needs to be checked also to find out where the voltage leak is happening.

But not for a long term solution.

Here's an idea to test while you are waiting for parts: if you have an extra AD8677 op amp, wire one up by itself on the bench in a bread board or dead bug wire it, with +5 and -5 supplies, then apply input on pin 2 with pin 3 grounded; apply 3, 3.5, 4 volts thru a resistor to pin 2 and observe if it gets pulled back down to 3.5 when the input is higher than that. If you don't have enough power supplies, just use +5 and return for supplies since you are only testing the input with a positive signal if should still bleed off the excess.

i was quite surprised to see all the hidden vias under the PWM chip.

The hash in the + and - supplies is occurring at 50 and 100 Hz, so i suspect that noise is from the mains frequency, the burst width is about 6msec.

The switch control lines AD and BC are at about 53kHz, which is the expected frequency from the PWM chip, so the little resistor and capacitor on TL494 pins 5 and 6 are doing their job. The waveform appears symmetric so the deadtime control is not out of whack.

Just looking at the small band about the mean it would seem the ripple is about 130mV.

If the op amp output on pin 6 is the inverted equal to the input on VH, then it is likely working okay and no need to disturb or swap it out--the problem seems to be downstream of there, such as the 4066, or the signal transformer, or the output 4066 and LPF.

There are no easy access vias for test points for the other end, but that all needs to be checked also to find out where the voltage leak is happening.