You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why do Li-ion Batteries die?

- Thread starter FiddlerJohn

- Start date

Help Support Mitsubishi i-MiEV Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

sandange

Well-known member

Thanks for the link

Learned a lot

Learned a lot

Mart

Well-known member

There's a career for some young guy or gal. I wonder how Toyota's investment in solid state batteries will play out, with no electrolyte to transfer.

This presentation (slide 12 http://www.transportation.anl.gov/pdfs/B/805.PDF )says that both very fast charging and very slow charging can lead to lithium plating/dendrite formation, especially in the cold. Looks like Goldilocks was right; I'll stick with L2 as my normal method.

Lithium plating more likely during

• High rates of charging

• High states of charge

• Longer charge duration

• Low temperatures

Lithium plating more likely during

• High rates of charging

• High states of charge

• Longer charge duration

• Low temperatures

jray3, the slide is entitled "Greater Fast Charge Ability…"

They specifically say "High power charge rates may lead to side reaction, ie., Lithium plating."

My take on this slide is that the high power is delivered in pulses and that they're comparing one-second pulses with 10-second pulses at a 5C level. Since our batteries IIRC are around 50Ah, we're talking about 250Amp charging pulses!

My take on both L1 and L2 is that they are so far removed from 5C (our L1 is about 0.06C) that their concerns don't apply.

At an EAA meeting a couple of years ago there was a presentation by the chief scientist of a local Lithium cell startup. I specifically asked him if there were any adverse issues caused by charging too slowly. After he recovered from his shock, he allowed as there were none. The main thrust of their development was thermal control at high charging rates and that since at low charging rates there were no thermal issues then he allowed as there was no problem.

Nevertheless, in this presentation they do say "Longer charge duration", so you do have a point. Next time any of us run across anyone involved in Lithium cell design, let's ask them about Lithium plating and extended low current charge durations.

There are a number of us iMiEV owners who continue to use L1 (including me, interspersed with occasional L2) … let's see how we fare in a few years.

They specifically say "High power charge rates may lead to side reaction, ie., Lithium plating."

My take on this slide is that the high power is delivered in pulses and that they're comparing one-second pulses with 10-second pulses at a 5C level. Since our batteries IIRC are around 50Ah, we're talking about 250Amp charging pulses!

My take on both L1 and L2 is that they are so far removed from 5C (our L1 is about 0.06C) that their concerns don't apply.

At an EAA meeting a couple of years ago there was a presentation by the chief scientist of a local Lithium cell startup. I specifically asked him if there were any adverse issues caused by charging too slowly. After he recovered from his shock, he allowed as there were none. The main thrust of their development was thermal control at high charging rates and that since at low charging rates there were no thermal issues then he allowed as there was no problem.

Nevertheless, in this presentation they do say "Longer charge duration", so you do have a point. Next time any of us run across anyone involved in Lithium cell design, let's ask them about Lithium plating and extended low current charge durations.

There are a number of us iMiEV owners who continue to use L1 (including me, interspersed with occasional L2) … let's see how we fare in a few years.

A bit off topic, however why would anyone use L1 if they had the ability to use L2 charge rates with their I-MiEV? The efficiency of the charging cycle is a lot lower during L1 charging due to fixed losses from the 12 volt systems that operate during any charging session. The shorter the time period is that you are actually charging, the higher the efficiency. Our 8 amp EVSE's make the problem even worse.

$87.99

WYMZF Car Covers, for Mitsubishi i-MiEV 2010-2021 All Weather Outdoor Indoor Waterproof UV Resistant Dustproof Windproof Protection, Auto Accessories,B

DATONGSHIPINGCHENGQUDAYUANBAIHUODIANGERENDUZI

$32.99

RAOXIO 4 Pcs Car Door Protector Edge Guards for Mitsubishi i MiEV 2009-2020, Scratch and Abrasion Resistant Car Door Edge Guards Carbon Fiber Texture Door Edge Guard Accessories

kunmingxiaojingmanshangmaoyouxiangongsi

PV1

Well-known member

In cold weather, the longer charge of level 1 keeps them active and therefore warmer than hitting an hour or two of level 2 and then nothing. Nice to have for better regen and range, but this is where the charge duration factor comes in. Although less efficient, it allows for better range.

siai47, very well phrased summary explaining the lower-cost aspect of using L2, with which I completely agree. In my case, I originally elected to use the L1 EVSE in the belief that the lower the charging current the lower the temperature inside the battery case, even at these low L1 and L2 rates. Energy consumption cost in my case doesn't matter with my cost-positive PV system.siai47 said:A bit off topic, however why would anyone use L1 if they had the ability to use L2 charge rates with their I-MiEV? The efficiency of the charging cycle is a lot lower during L1 charging due to fixed losses from the 12 volt systems that operate during any charging session. The shorter the time period is that you are actually charging, the higher the efficiency. Our 8 amp EVSE's make the problem even worse.

What I do is start charging in the middle of the night using the Remote (having allowed the pack to cool off from the previous day's driving), timing the charge to stop around 14 bars just as one of us goes off in the car in the morning. I used to use the Mitsu L1 EVSE but now keep it in the car and instead use the Clipper Creek L1 12A EVSE, which works well with our Remote. Even though now I agree that the difference between L1 and L2 in terms of battery heating is probably negligible, I'm continuing to use L1 because my Remote is unhappy with my SPX L2 EVSE and fails to properly program. My SPX is on a mechanical timer to turn it off, but I'm too lazy to rig up a separate easy-to-use time-delay and interval timer for it.

Since this topic is allied with Battery Life, to conclusively put this issue to bed, now that we have CaniOn, one of us should perhaps perform a controlled test measuring ambient temperature and internal temperatures at the 8A L1, 12A L1, and 12.8A L2 charge rates? Oooh, sounds like a science project - anyone have any kids that might want to undertake this for credit in school?

I'm in Joe's camp on this too - I choose L1 or L2 mostly based on when I would like the charge cycle to end and usually at around 80% of charge. If I get home in the evening after dinner with 40% or so SOC remaining, I'll plug it into L2 for 2 or 3 hours and pull the plug before we go to bed at around 80%. If I go somewhere in the morning and plug it in before noon, I'll usually use L1 so I can leave it for 5 or 6 hours without it charging to 100%

It's really handy to have both available, depending on how you want to charge. I probably use L1 about 75% or the time, even though I do understand it's a few percentage points less efficient. I try to not let it fully charge 90% of the time . . . . and the few times I do let it recharge fully to 100%, I time it so we're leaving shortly after the charge cycle ends. I almost never let the car sit with a 100% charge for more than an hour or so

The way we use the car, if I could only have one EVSE, it would be a 12 amp L1 unit . . . . but it's nice to have both. Even when using L2, I keep it at 12 amps so the charger is never running at 100% of capacity

Don

It's really handy to have both available, depending on how you want to charge. I probably use L1 about 75% or the time, even though I do understand it's a few percentage points less efficient. I try to not let it fully charge 90% of the time . . . . and the few times I do let it recharge fully to 100%, I time it so we're leaving shortly after the charge cycle ends. I almost never let the car sit with a 100% charge for more than an hour or so

The way we use the car, if I could only have one EVSE, it would be a 12 amp L1 unit . . . . but it's nice to have both. Even when using L2, I keep it at 12 amps so the charger is never running at 100% of capacity

Don

This last issue of the Electric Auto Association's Current EVents (March 2014) summarized some serious research into Lithium battery life, focusing on empirical data and not modeling. Here is the highly-technical presentation I have on my list of things to watch: http://www.youtube.com/watch?v=pxP0Cu00sZs by Professor Jeff Dahn from Canada’s Dalhousie University, a research-intensive Halifax, Nova Scotia-based institution.

A key message from all this is to keep batteries cool and don't keep the battery charged at 100%, especially at high temperatures!

A key message from all this is to keep batteries cool and don't keep the battery charged at 100%, especially at high temperatures!

Mart

Well-known member

Although the Idaho National Lab used Leafs for testing, it seems using the DC quick charge doesn't damage the battery much. Undoubtedly it saves wear and tear on the inverter.

http://green.autoblog.com/2014/03/17/dc-fast-charging-not-as-damaging-to-ev-batteries-as-expected/

http://green.autoblog.com/photos/nissan-leaf-dc-fast-charging-test-charts/#photo-2488145

http://green.autoblog.com/2014/03/17/dc-fast-charging-not-as-damaging-to-ev-batteries-as-expected/

http://green.autoblog.com/photos/nissan-leaf-dc-fast-charging-test-charts/#photo-2488145

What's most interesting are the charts on page seven of Shirk's presentation (click the image above to enlarge), which show the energy capacity of each of the four vehicles. When they were new, the four batteries were each tested to measure their energy capacity and given a 0 capacity loss baseline. They were then tested at 10,000, 20,000, 30,000 and 40,000 miles, and at each point, the DC-only EVs had roughly the same amount of battery loss as the Level 2 test subjects. The DC cars did lose a bit more at each test, but only around a 25-percent overall loss after 40k, compared to 23 percent for the Level 2 cars. Simanaitis' takeaway is that, "INL data suggest that the amount of degradation depends more on the miles traveled than on the nature of recharging." The tests are part of the INLs' Advanced Vehicle Testing Activity work and a final report is forthcoming.

These initial numbers from IPL do mesh with other research into DC fast charging, though. Mitsubishi said daily fast charging wouldn't really hurt the battery in the i-MiEV and MIT tests of a Fisker Karma battery showed just 10-percent loss over 1,500 rapid charge-discharge cycles.

Malm

Well-known member

In my case (portuguese i-MiEV), using DC quick charge will be better for the battery because the car gives cold air to the battery. Temperatures will not rise above 31º/32ºC. If I do a slow charge in the summer by day, temperatures will rise above 40º C. So, for the i-MiEV, in Arizona, quick charges will be, most of the times, better then slow charges.

Interesting observation, Malm. I'll be curious to see if that can be gleaned from any long-term reports. I've seen i-MiEV police vehicles in Italy and electric utility-owned cars in Hong Kong, but don't know if either of those warm-climate fleets get much DCFC.

tonymil

Well-known member

Mart said:Although the Idaho National Lab used Leafs for testing, it seems using the DC quick charge doesn't damage the battery much. Undoubtedly it saves wear and tear on the inverter.

http://green.autoblog.com/2014/03/17/dc-fast-charging-not-as-damaging-to-ev-batteries-as-expected/

http://green.autoblog.com/photos/nissan-leaf-dc-fast-charging-test-charts/#photo-2488145

What's most interesting are the charts on page seven of Shirk's presentation (click the image above to enlarge), which show the energy capacity of each of the four vehicles. When they were new, the four batteries were each tested to measure their energy capacity and given a 0 capacity loss baseline. They were then tested at 10,000, 20,000, 30,000 and 40,000 miles, and at each point, the DC-only EVs had roughly the same amount of battery loss as the Level 2 test subjects. The DC cars did lose a bit more at each test, but only around a 25-percent overall loss after 40k, compared to 23 percent for the Level 2 cars. Simanaitis' takeaway is that, "INL data suggest that the amount of degradation depends more on the miles traveled than on the nature of recharging." The tests are part of the INLs' Advanced Vehicle Testing Activity work and a final report is forthcoming.

These initial numbers from IPL do mesh with other research into DC fast charging, though. Mitsubishi said daily fast charging wouldn't really hurt the battery in the i-MiEV and MIT tests of a Fisker Karma battery showed just 10-percent loss over 1,500 rapid charge-discharge cycles.

What I found interesting about this report is how much battery capacity was lost at each stage. At 10,000 miles the cars lost an average of 6%. From 10,000 to 20,000 they lost an average of 2.5%. At 30,000 they lost around 8%. At 40,000 they lost almost 10%. So for some reason the amount of capacity lost from 10,000 to 20,000 was less than from 0 to 10,000, but then the percentage loss increased the two years thereafter. I wonder if this has to do with the conditions under which they were driven or if it somehow relates to the technology.

Just to clarify, my numbers add up to more than 25% because I'm comparing year three to year two and year four to year three. The study looked at each year in comparison to the starting point of capacity.

Malm

Well-known member

Tonymil said "Just to clarify, my numbers add up to more than 25% because I'm comparing year three to year two and year four to year three. The study looked at each year in comparison to the starting point of capacity."

The study, I think (I can be wrong), was done in one year, maybe two. The 4 Leafs are from 2012, we are in early 2014. So 40.000 miles in one or two years, not four. Maybe in just one year, and the low value of degradation in the second measurement was taken in the end of winter. In Arizona, in winter, temperatures are substancially lower then in summer. And TEMPERATURE is the most significant factor that acelerates degradation. Temperature, temperature, and temperature. That's why the i-MiEV is not so susceptable to fast charges, because don't let them going hotter. Leafs just can't do it.

The study, I think (I can be wrong), was done in one year, maybe two. The 4 Leafs are from 2012, we are in early 2014. So 40.000 miles in one or two years, not four. Maybe in just one year, and the low value of degradation in the second measurement was taken in the end of winter. In Arizona, in winter, temperatures are substancially lower then in summer. And TEMPERATURE is the most significant factor that acelerates degradation. Temperature, temperature, and temperature. That's why the i-MiEV is not so susceptable to fast charges, because don't let them going hotter. Leafs just can't do it.

BlueLightning

Well-known member

Temperature dependent ageing mechanisms in Lithium-ion batteries – A Post-Mortem study. Journal of Power Sources, Volume 262, 15 September 2014, Pages 129–135

http://www.sciencedirect.com/science/article/pii/S0378775314004352

Abstract

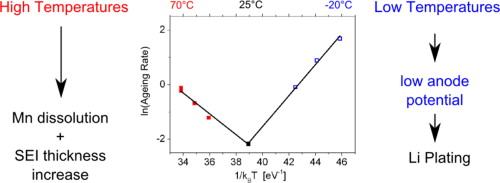

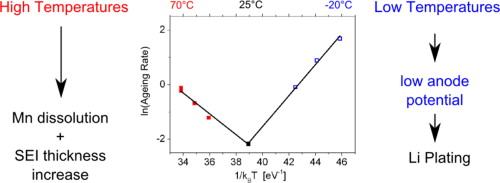

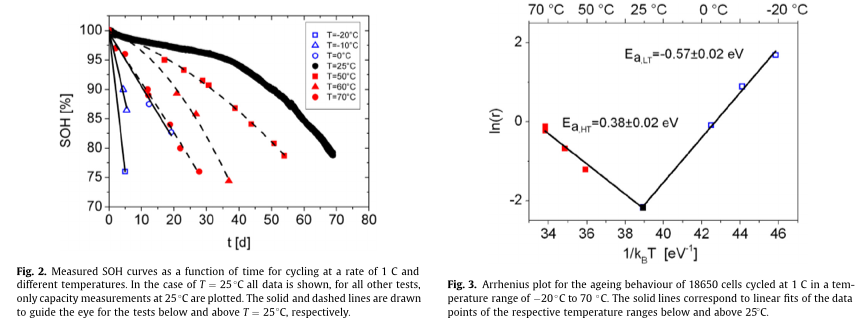

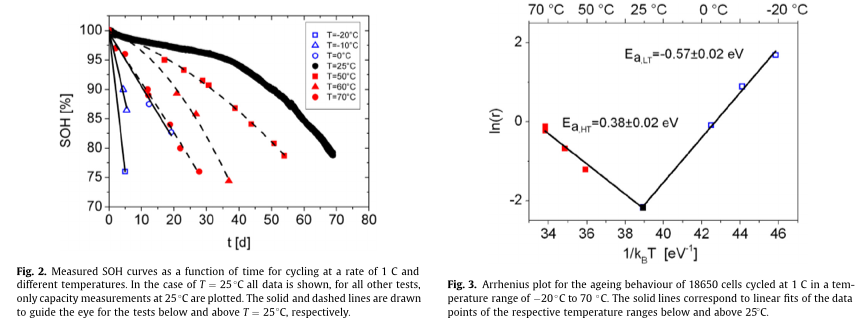

The effects of temperatures in the range of −20 °C to 70 °C on the ageing behaviour of cycled Lithium-ion batteries are investigated quantitatively by electrochemical methods and Post-Mortem analysis. Commercial 18650-type high-power cells with a LixNi1/3Mn1/3Co1/3O2/LiyMn2O4 blend cathode and graphite/carbon anode were used as test system. The cells were cycled at a rate of 1 C until the discharge capacity falls below 80% of the initial capacity. Interestingly, an Arrhenius plot indicates two different ageing mechanisms for the ranges of −20 °C to 25 °C and 25 °C to 70 °C. Below 25 °C, the ageing rates increase with decreasing temperature, while above 25 °C ageing is accelerated with increasing temperature. The aged 18650 cells are inspected via scanning electron microscopy (SEM), energy dispersive X-ray analysis (EDX), inductively coupled plasma (ICP), measurements of electrode thickness and X-ray diffraction (XRD) after disassembly to learn more about the chemical reasons of the degradation. The effect of different temperatures on the electrode polarizations are evaluated by assembling electrodes in pouch cells with reference electrode as a model system. We find that the dominating ageing mechanism for T < 25 °C is Lithium plating, while for T > 25 °C the cathodes show degeneration and the anodes will be increasingly covered by Solid Electrolyte Interface SEI layers.

State of Health decrease approximately with the same rate for T = 70 °C and for T = 0 °C

Effect of low and high temperatures on the ageing rate of Lithiu

State of Health Estimation of Li ion Batteries: Cycle Life Test Methods

http://komar.bitcheese.net/files/JensGroot.pdf

See curves Voltage versus SoC or Voltage versus Capacity giving informations about Battery State of Life, pdf, page 97 or Paper page 85, Chapter 7 Cell Ageing Analysis, 7.1 Galvanostatic Voltage Profiles

.....

http://www.sciencedirect.com/science/article/pii/S0378775314004352

Abstract

The effects of temperatures in the range of −20 °C to 70 °C on the ageing behaviour of cycled Lithium-ion batteries are investigated quantitatively by electrochemical methods and Post-Mortem analysis. Commercial 18650-type high-power cells with a LixNi1/3Mn1/3Co1/3O2/LiyMn2O4 blend cathode and graphite/carbon anode were used as test system. The cells were cycled at a rate of 1 C until the discharge capacity falls below 80% of the initial capacity. Interestingly, an Arrhenius plot indicates two different ageing mechanisms for the ranges of −20 °C to 25 °C and 25 °C to 70 °C. Below 25 °C, the ageing rates increase with decreasing temperature, while above 25 °C ageing is accelerated with increasing temperature. The aged 18650 cells are inspected via scanning electron microscopy (SEM), energy dispersive X-ray analysis (EDX), inductively coupled plasma (ICP), measurements of electrode thickness and X-ray diffraction (XRD) after disassembly to learn more about the chemical reasons of the degradation. The effect of different temperatures on the electrode polarizations are evaluated by assembling electrodes in pouch cells with reference electrode as a model system. We find that the dominating ageing mechanism for T < 25 °C is Lithium plating, while for T > 25 °C the cathodes show degeneration and the anodes will be increasingly covered by Solid Electrolyte Interface SEI layers.

State of Health decrease approximately with the same rate for T = 70 °C and for T = 0 °C

Effect of low and high temperatures on the ageing rate of Lithiu

State of Health Estimation of Li ion Batteries: Cycle Life Test Methods

http://komar.bitcheese.net/files/JensGroot.pdf

See curves Voltage versus SoC or Voltage versus Capacity giving informations about Battery State of Life, pdf, page 97 or Paper page 85, Chapter 7 Cell Ageing Analysis, 7.1 Galvanostatic Voltage Profiles

.....

RobertC

Well-known member

Interesting study.

The lithium-ion batteries tested, the 18650 cell used in the Tesla, have the same lithium-manganese dioxide chemistry as the LEV50 batteries used in the MiEV.

The conclusion of this study is that 25°C (77°F) is the temperature at which the batteries exhibit the slowest aging, or maintain the best state-of-health (SOH).

However, it appears that the batteries age faster below 25°C than they do above 25°C.

In other words, the batteries will age faster in extreme cold than extreme heat.

The following Figures 2 and 3 are from the study, and show that the batteries age the same at 0°C (32°F) and 70°C (158°F), with the fasted aging at -20°C (-4°F).

From:

Temperature dependent ageing mechanisms in Lithium-ion batteries – A Post-Mortem study

Thomas Waldmann, Marcel Wilka, Michael Kasper, Meike Fleischhammer, Margret Wohlfahrt-Mehrens

The study also concludes that:

The lithium-ion batteries tested, the 18650 cell used in the Tesla, have the same lithium-manganese dioxide chemistry as the LEV50 batteries used in the MiEV.

The conclusion of this study is that 25°C (77°F) is the temperature at which the batteries exhibit the slowest aging, or maintain the best state-of-health (SOH).

However, it appears that the batteries age faster below 25°C than they do above 25°C.

In other words, the batteries will age faster in extreme cold than extreme heat.

The following Figures 2 and 3 are from the study, and show that the batteries age the same at 0°C (32°F) and 70°C (158°F), with the fasted aging at -20°C (-4°F).

From:

Temperature dependent ageing mechanisms in Lithium-ion batteries – A Post-Mortem study

Thomas Waldmann, Marcel Wilka, Michael Kasper, Meike Fleischhammer, Margret Wohlfahrt-Mehrens

The study also concludes that:

- 1. It is important to include heating and cooling systems in lithium-ion battery packs in automotive applications.

2. Lithium-ion batteries need to be improved to be resistant against aging in a wider temperature range.

BlueLightning

Well-known member

Thanks to Malm, temperature effects far above 25 °C, (77°F) are well documented.

Malm main discovery is that regardless of an observed decrease in capacity, State of Charge changes over time to allow SOC=100% to correspond to a fully charged cell.

For temperature effects far below 25 °C, (77°F), we need another Malm

For 25°C (77°F) which is the temperature where the batteries exhibit the slowest aging, or maintain the best state-of-health (SOH), will my EV be a reference.

Every night Blue Lightning stays in an underground garage at nearly a fresh constant temperature. Every two days, before going to bed I plug it, so on the batteries have time to cool off.

I live in Normandy, Latitude 49° north, oceanic or temperate marine climate may be like Seattle in Washington State, since I drive electric, my driving is cool and from my bedroom on top the garage I can use Canion like a Baby Sleep Monitor....

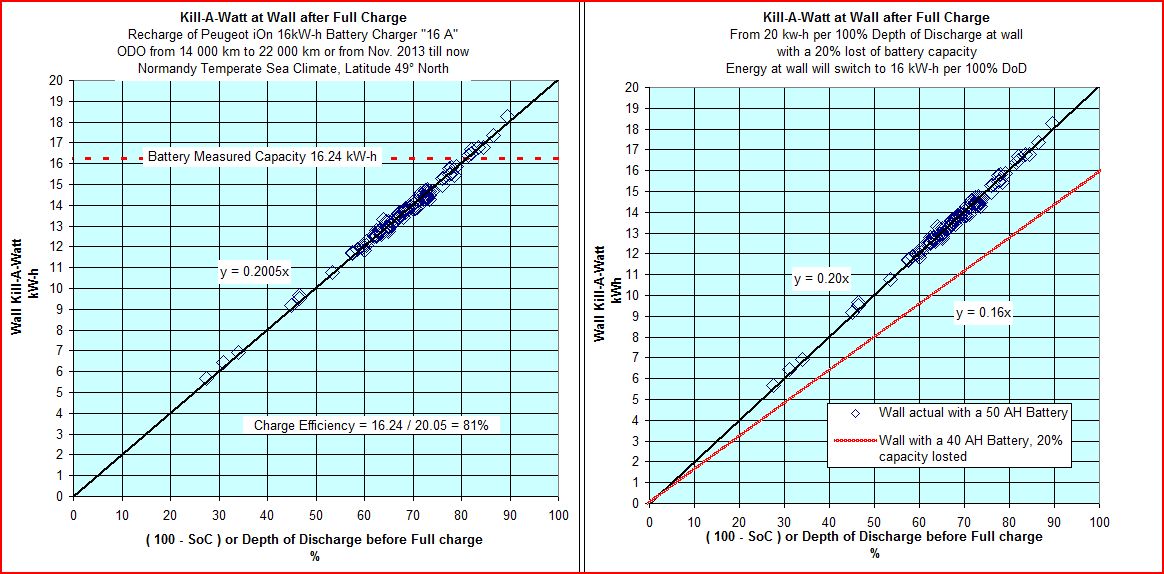

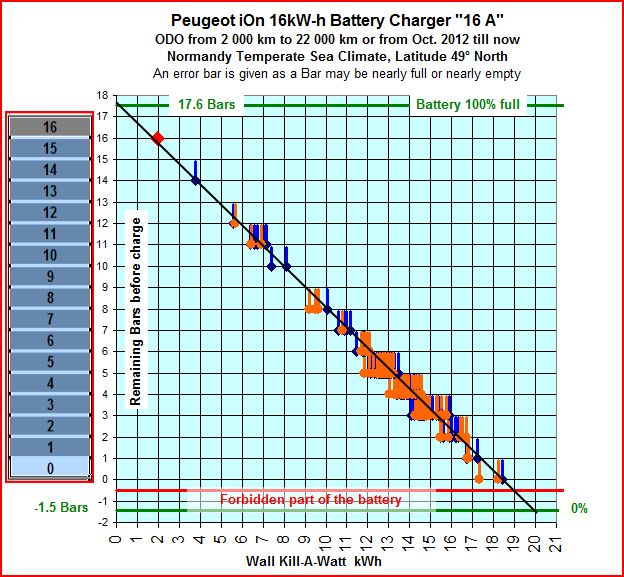

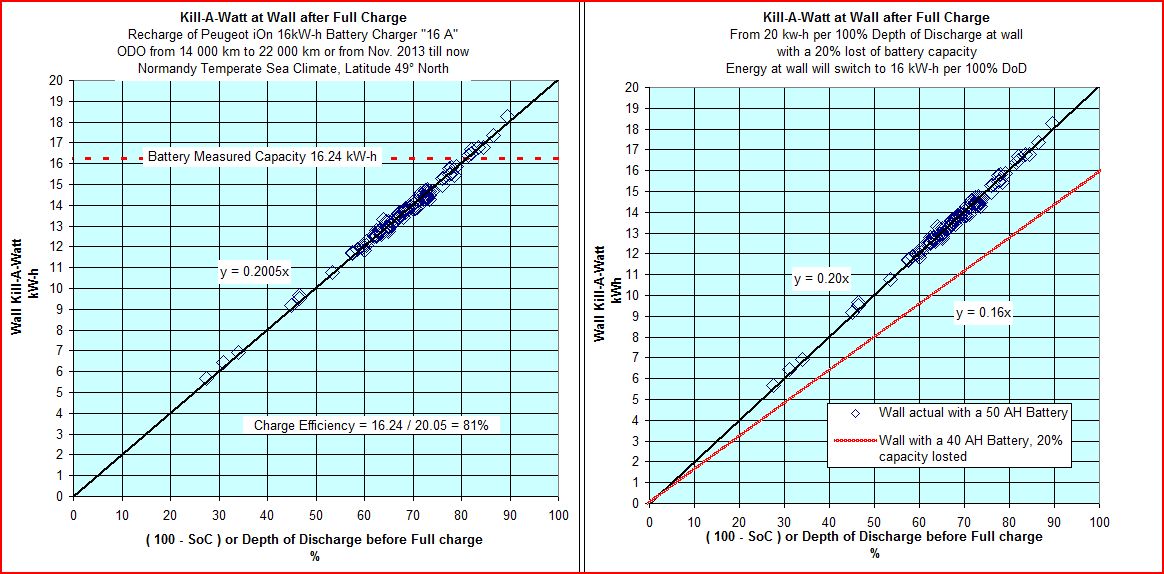

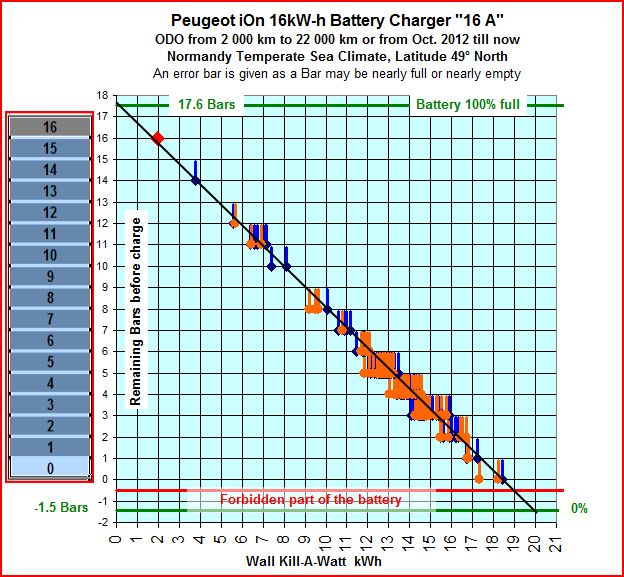

For the graphs, a Depth of Discharge of 0% means there is no rooms to put any juice in the Battery, at 50% DoD before full charge a kill a Watt at the Wall will show me a value of 10 kW-h after a full charge, a DoD of 100% give a theoretical charge of 20 kW-h for an empty battery.

This theoretical amount is helpful to get an Energy Storage efficiency and 81 % seems to be a good number. When this charge of 20 kW-h for an empty battery will decrease to 16 kW-h for a 100% DoD, then I will know there is a 20 % battery capacity lost.

By the way, I was horrified some folks were emptying at high risk their battery to get this magic number of 20 kW-h, as you can see, several measures, a simple projection and then you get this magic number of 20 kW-h or less....

As long my kill a Watt values will not give any deviations from that line, 0 to 20 kW-h, this will show a good Battery State of Health.

5040 AH Kill a Watt versus Depht of Discharge before full charge

Kill a Watt versus remaining bars before full charge

Malm main discovery is that regardless of an observed decrease in capacity, State of Charge changes over time to allow SOC=100% to correspond to a fully charged cell.

For temperature effects far below 25 °C, (77°F), we need another Malm

For 25°C (77°F) which is the temperature where the batteries exhibit the slowest aging, or maintain the best state-of-health (SOH), will my EV be a reference.

Every night Blue Lightning stays in an underground garage at nearly a fresh constant temperature. Every two days, before going to bed I plug it, so on the batteries have time to cool off.

I live in Normandy, Latitude 49° north, oceanic or temperate marine climate may be like Seattle in Washington State, since I drive electric, my driving is cool and from my bedroom on top the garage I can use Canion like a Baby Sleep Monitor....

For the graphs, a Depth of Discharge of 0% means there is no rooms to put any juice in the Battery, at 50% DoD before full charge a kill a Watt at the Wall will show me a value of 10 kW-h after a full charge, a DoD of 100% give a theoretical charge of 20 kW-h for an empty battery.

This theoretical amount is helpful to get an Energy Storage efficiency and 81 % seems to be a good number. When this charge of 20 kW-h for an empty battery will decrease to 16 kW-h for a 100% DoD, then I will know there is a 20 % battery capacity lost.

By the way, I was horrified some folks were emptying at high risk their battery to get this magic number of 20 kW-h, as you can see, several measures, a simple projection and then you get this magic number of 20 kW-h or less....

As long my kill a Watt values will not give any deviations from that line, 0 to 20 kW-h, this will show a good Battery State of Health.

5040 AH Kill a Watt versus Depht of Discharge before full charge

Kill a Watt versus remaining bars before full charge

RobertC

Well-known member

While we still do not know our battery capacity loss or battery state-of-health (SOH), we have seen on this forum three battery pack failures (and possibly four including Sandange), all in vehicles that operated in cold weather areas.BlueLightning said:For temperature effects far below 25 °C, (77°F), we need another Malm

These battery pack failures were:

Member, Date, Location, Avg. Low Temperature in January

tonymil, 6/2/13, Latham, NY, -9 °C, (15°F)

nt2w, 9/3/13, Potsdam, NY, -14 °C, (6°F)

dniemeyer99, 2/14/14, Sudbury, Ontario, -19°C (-2°F)

Sandange, 4/10/14, St. Sauveur, Quebec, -18°C (-1°F)

I wish we had the postmortem from Mitsubishi on the cause of these battery pack failures.

PV1

Well-known member

I wonder what the lowest experienced temperature was, and whether or not the car was driven or charged during it? My car spent 2 or 3 separate nights below 0 F, and I didn't notice anything alarming (other than the car severely limiting regen strength). The morning after the coldest night, I parked it in a 70 F garage with the fan pumping air into the battery and charging the battery.

From batteryuniversity.com with my bold:

Makes me wonder why the heater won't kick in until 5 F?

By the way, how did you get the degree symbol (°)?

From batteryuniversity.com with my bold:

Li‑ion batteries offer reasonably good charging performance at cooler temperatures and allow fast-charging in a temperature bandwidth of 5 to 45°C (41 to 113°F). Below 5°C, the charge current should be reduced, and no charging is permitted at freezing temperatures. During charge, the internal cell resistance causes a slight temperature rise that compensates for some of the cold. With all batteries, cold temperature raises the internal resistance.

Many battery users are unaware that consumer-grade lithium-ion batteries cannot be charged below 0°C (32°F). Although the pack appears to be charging normally, plating of metallic lithium can occur on the anode during a subfreezing charge. The plating is permanent and cannot be removed with cycling. Batteries with lithium plating are known to be more vulnerable to failure if exposed to vibration or other stressful conditions. Advanced chargers, such as those made by Cadex, prevent charging Li-ion below freezing.

Manufactures continue to seek ways to charge Li-ion below freezing and low-rate charging is indeed possible with most lithium-ion cells; however, it is outside the specified (and tested) limits of most manufacturers’ products. Low-temperature charging would need to be addressed on a case-by-case basis and would be manufacturer and application dependent. According to information received from university research centers, the allowable charge rate at –30°C (–22°F) is 0.02C. At this low current, a 1,000mAh Li-ion could only charge at 20mA, and this would take more than 50 hours to reach full charge.

Some Li-ion cells developed for power tool and EV applications can be charged at temperatures down to –10°C (14°F) at a reduced rate. To charge at a higher rate, Li-ion systems for automotive propulsion systems require a heating blanket. Some hybrid cars circulate warm cabin air through the batteries to raise the battery temperature, while high-performance electric cars heat and cool the battery with a liquid agent.

Makes me wonder why the heater won't kick in until 5 F?

By the way, how did you get the degree symbol (°)?

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 0

- Views

- 4K

- Replies

- 6

- Views

- 3K