DBMandrake

Well-known member

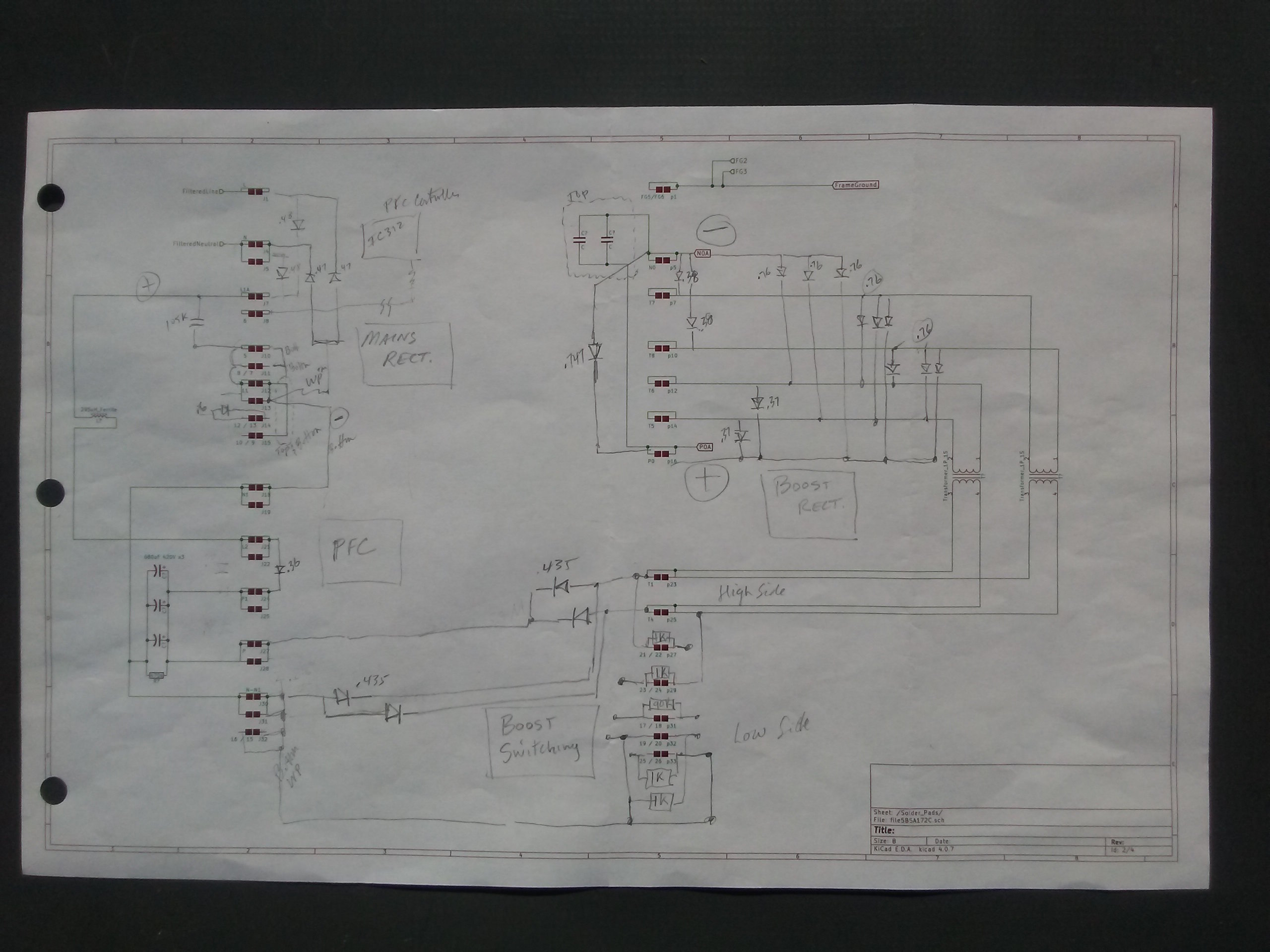

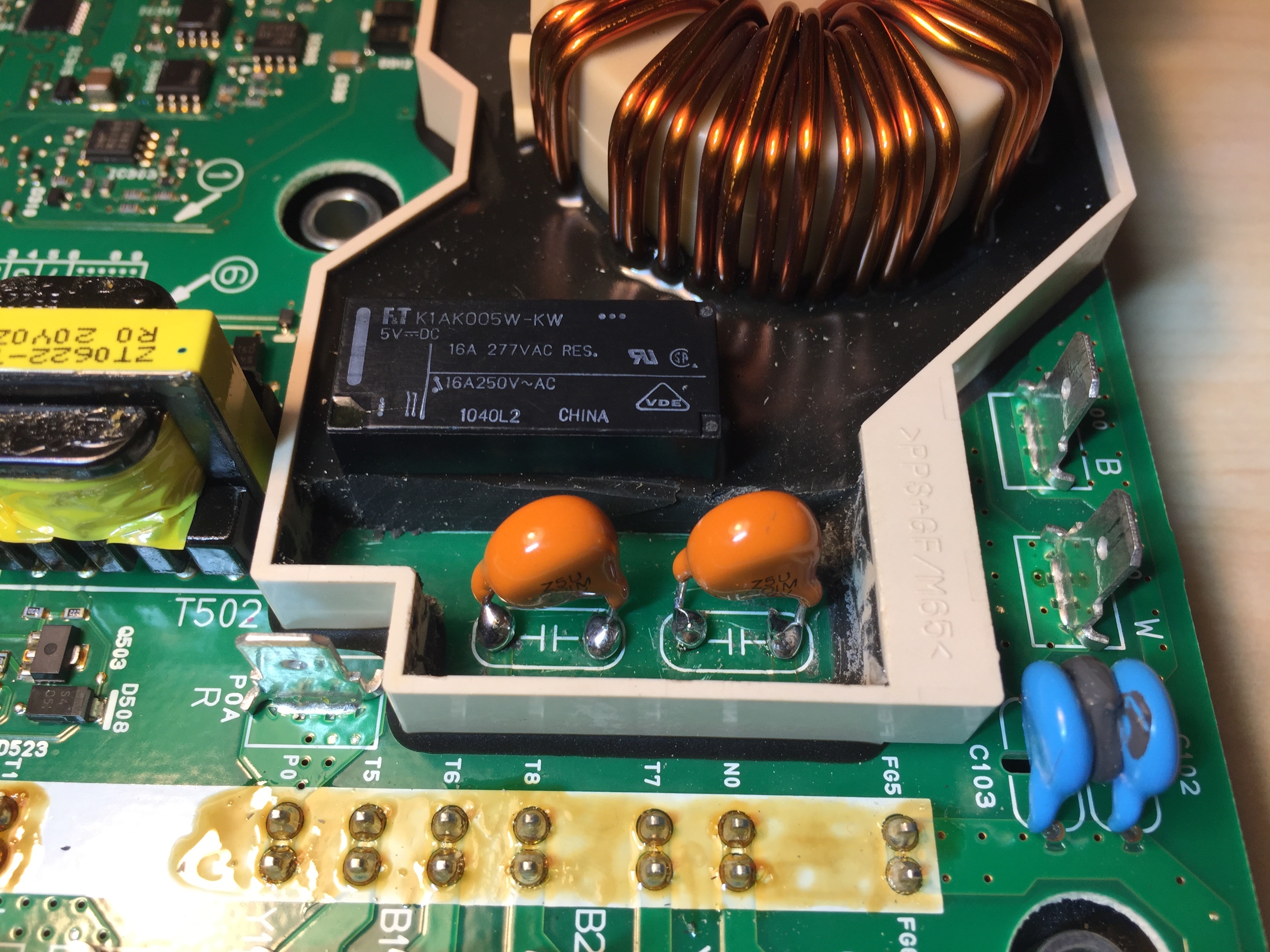

More progress. With a scapel and wooden scraper I managed to clear out a neat rectangular area to remove the old capacitors. I cut them off their own legs part way up which gave me about 2mm of leg left in the board to work with.

The caps I ordered have a slightly wider leg spacing than the originals but that actually worked out perfectly as I was able to wrap them around the pins in a U shape to create a good solder fillet joint:

It's not until seeing them side by side that I realised just how much beefier these caps are than the original - they're 6kV rated instead of the 2kV of the originals, only slightly larger in diameter, but about 3 times as thick! :twisted:

I was able to solder onto the leg stumps at the top without melting or causing a dry joint on the soldered joints under the board - there is quite a large gap between the waffle plate and the PCB so you can shine a torch into the gap and see the original soldered joints to make sure they're not disturbed.

The gap is so large that I reckon if there were no stumps to solder to you could possibly insert the component right through the hole, apply the soldering iron to the component leg on the top side (with the caps sitting a little higher than normal) and apply solder to the underside of the board in the gap to the waffle plate... I considered doing it that way but decided to try soldering to the old stumps first.

I have some black high voltage high temperature neutral cure electrical RTV silicone that should be a pretty good match with the original - firm but still rubbery in case anyone ever has to go back in there again, however I'm not going to put it in until I've tested the relay.

So now I need to test the resistors and relay and components on the waffle board...

The caps I ordered have a slightly wider leg spacing than the originals but that actually worked out perfectly as I was able to wrap them around the pins in a U shape to create a good solder fillet joint:

It's not until seeing them side by side that I realised just how much beefier these caps are than the original - they're 6kV rated instead of the 2kV of the originals, only slightly larger in diameter, but about 3 times as thick! :twisted:

I was able to solder onto the leg stumps at the top without melting or causing a dry joint on the soldered joints under the board - there is quite a large gap between the waffle plate and the PCB so you can shine a torch into the gap and see the original soldered joints to make sure they're not disturbed.

The gap is so large that I reckon if there were no stumps to solder to you could possibly insert the component right through the hole, apply the soldering iron to the component leg on the top side (with the caps sitting a little higher than normal) and apply solder to the underside of the board in the gap to the waffle plate... I considered doing it that way but decided to try soldering to the old stumps first.

I have some black high voltage high temperature neutral cure electrical RTV silicone that should be a pretty good match with the original - firm but still rubbery in case anyone ever has to go back in there again, however I'm not going to put it in until I've tested the relay.

So now I need to test the resistors and relay and components on the waffle board...