There is an OEM fan on the radiator at the front of the car - Any thoughts on just making a mod to use that fan?

Many ICE cars have 12 volt cooling fans behind the radiator which are energized using a thermal switch on the radiator tank - When it gets hot enough, the fan comes on for long enough to cool things down until the coolant switch de-energizes. Something like this shouldn't be too hard to fabricate. Hook power to the thermal switch 24/7 and just let it do it's thing . . . . the fan would automatically run anytime it's needed

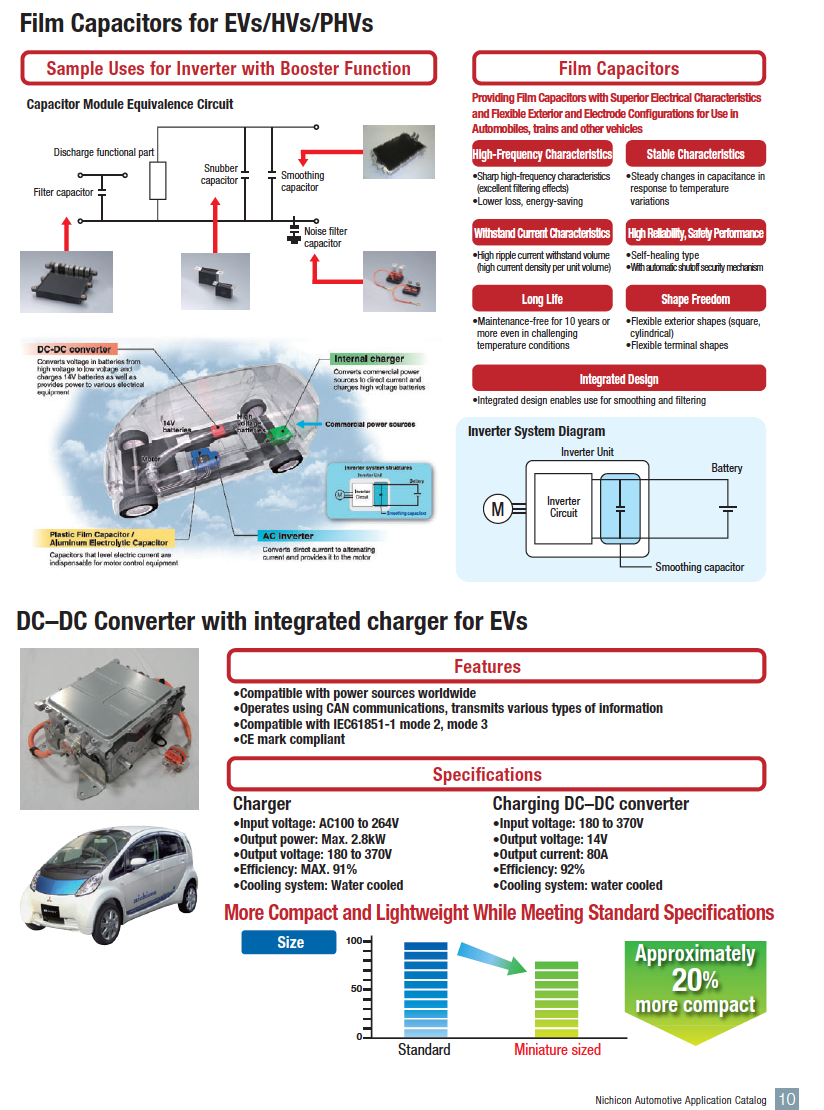

If the charger is water cooled, I like the idea of making that work, rather than blowing air on it

Don

Many ICE cars have 12 volt cooling fans behind the radiator which are energized using a thermal switch on the radiator tank - When it gets hot enough, the fan comes on for long enough to cool things down until the coolant switch de-energizes. Something like this shouldn't be too hard to fabricate. Hook power to the thermal switch 24/7 and just let it do it's thing . . . . the fan would automatically run anytime it's needed

If the charger is water cooled, I like the idea of making that work, rather than blowing air on it

Don