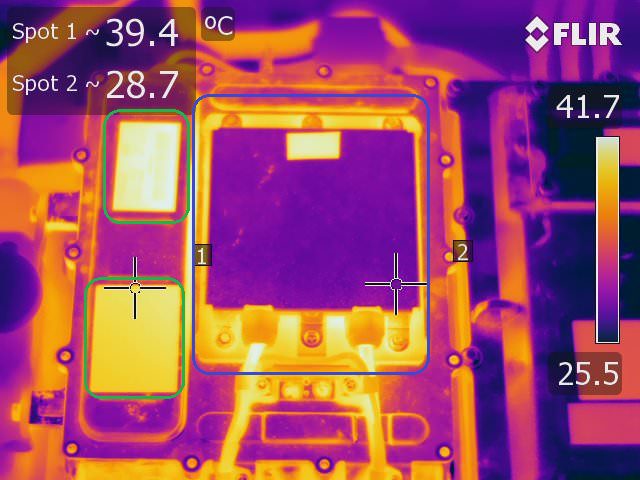

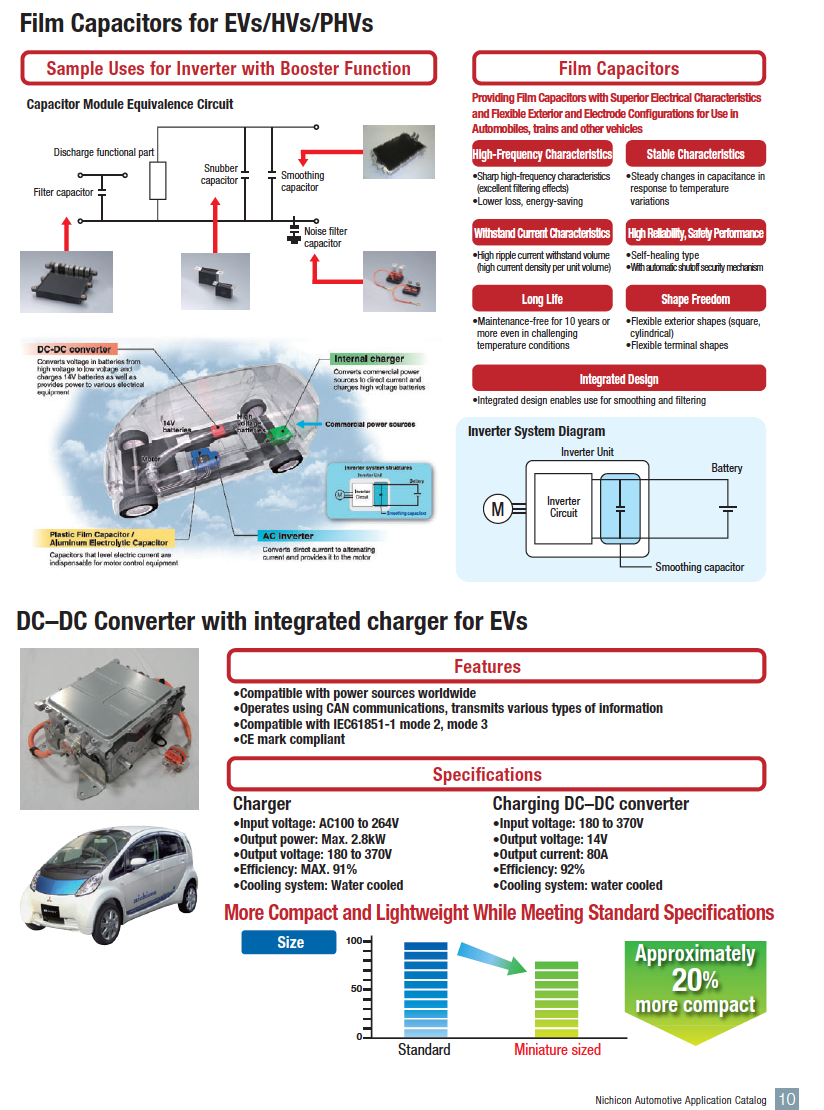

kiev said:The box has a nichicon part number, and looking thru their website i found they take credit for the miev OBC. In fact they claim that it worked so well for Mitsubishi that Nissan converted over to using their design in the Leaf.

Here is a page from a product brochure:

So i would say that nichicon is to blame if there are any thermal issues. Wonder if we could buy them direct without getting middle-manned by Mits?

Very cool info

anyone ever get any information on removing the top speed limiter or the torque limiting that seems to occur? "re map" the MCU??

the Pikes Peak ImiEv Evolution apparently ran 3 imiev motors and they were all boosted up to 80kW and higher RPM...

my project isn't "normal" so more power for temporary bursts would be great.