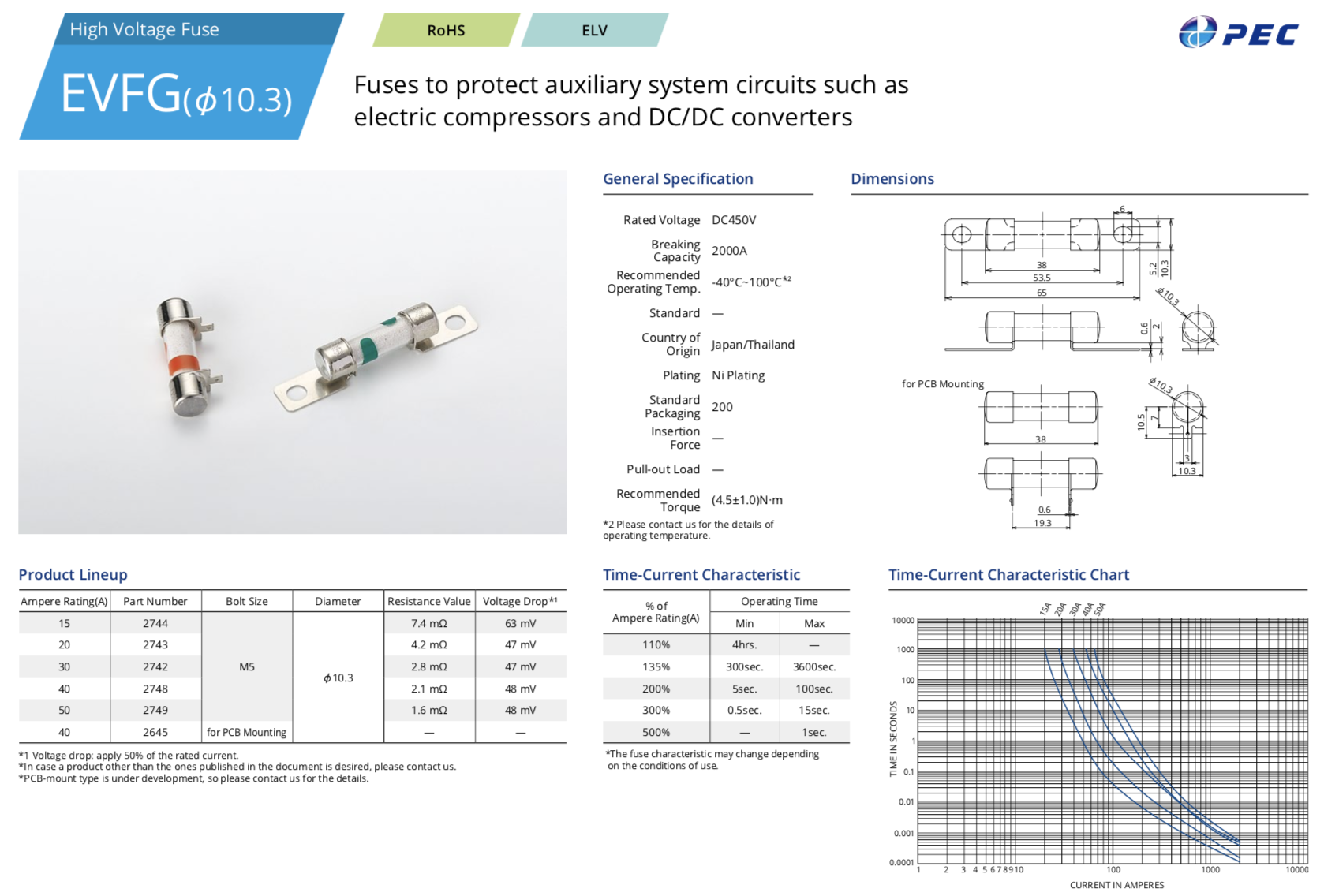

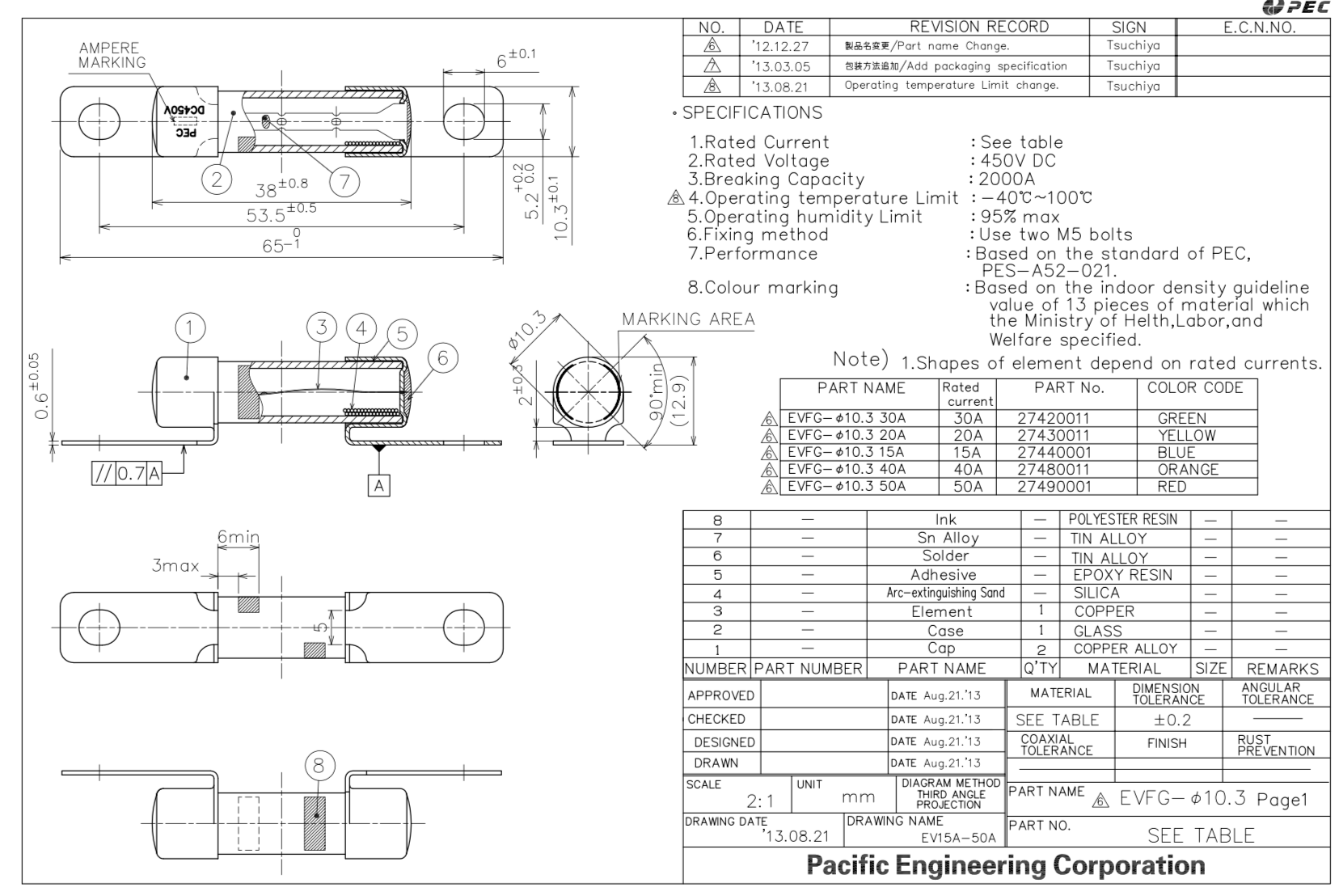

If for some reason the Motor Control Unit fuse blows, then the On-Board Chargger (OBC) and DCDC converter (High Voltage-to-12VDC) will no longer function, since they have lost their connection to the Battery Pack.

If the fuse blows during operation of the OBC, then it is very likely that the two snubber capacitors in the HV output section will also be destroyed. This scenario has been reported dozens of times in the past 2 years in the OBC Troubleshooting and Repair thread.

So looking at this another way-- could the fuse have a limited lifetime due to age, wear and tear, etc?

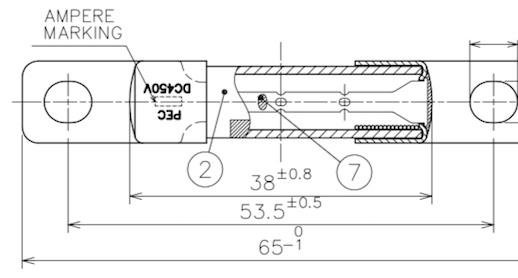

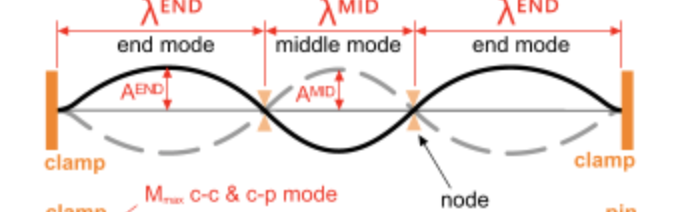

Environmental lifetime factors for fuses are not listed in the datasheets, but i would suggest that automotive electronics has a significant vibration factor for which stationary applications are not usually exposed.

What if the combination of repeated thermal cycling during normal OBC and DCDC operation, plus the mechanical shock and vibration from normal driving on our typically smooth and pothole-free highways over several years, has caused the fuse filament element to develop metal fatigue cracks leading to breakdown?

Could this be the root cause of the numerous OBC failures?

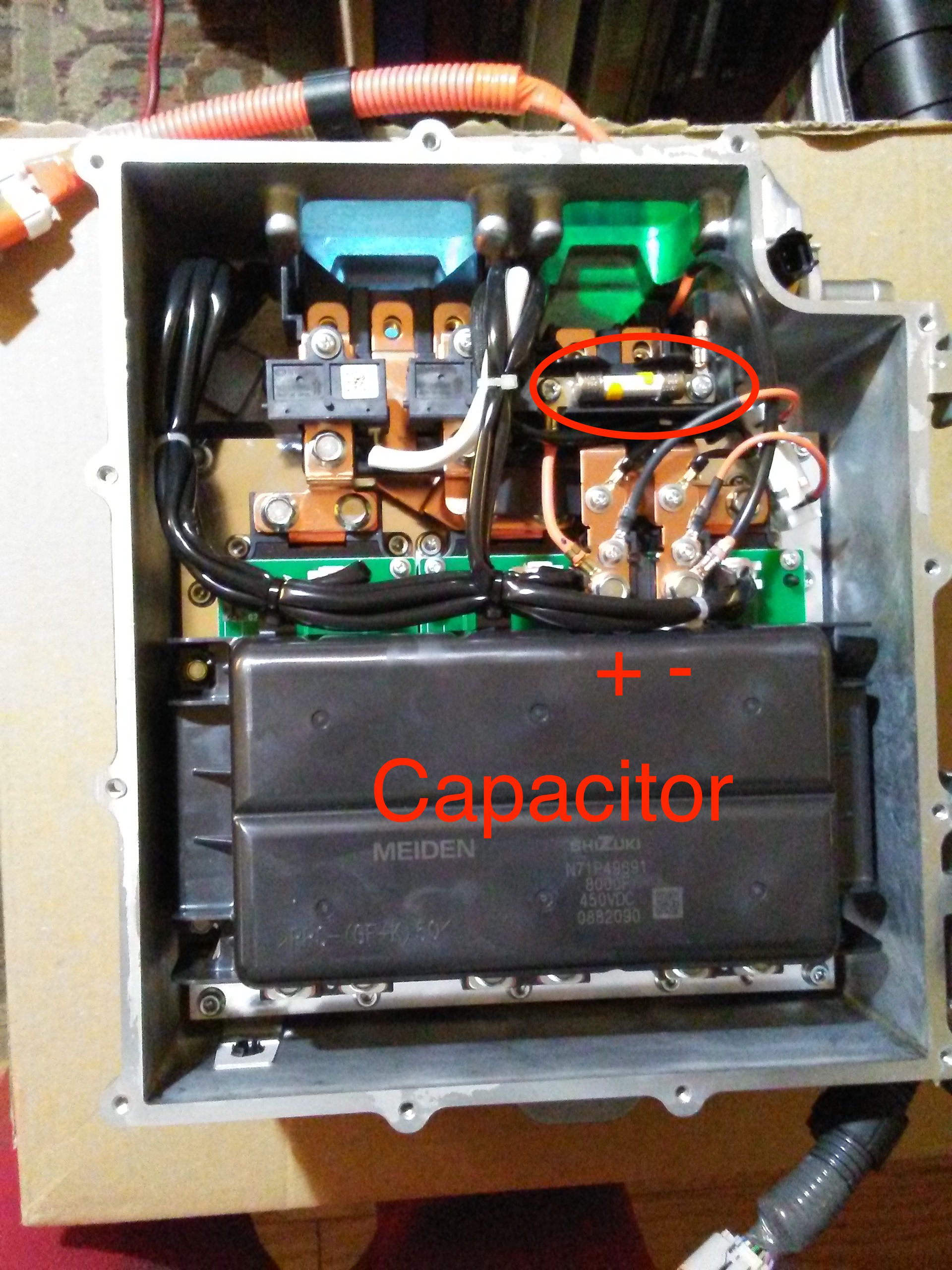

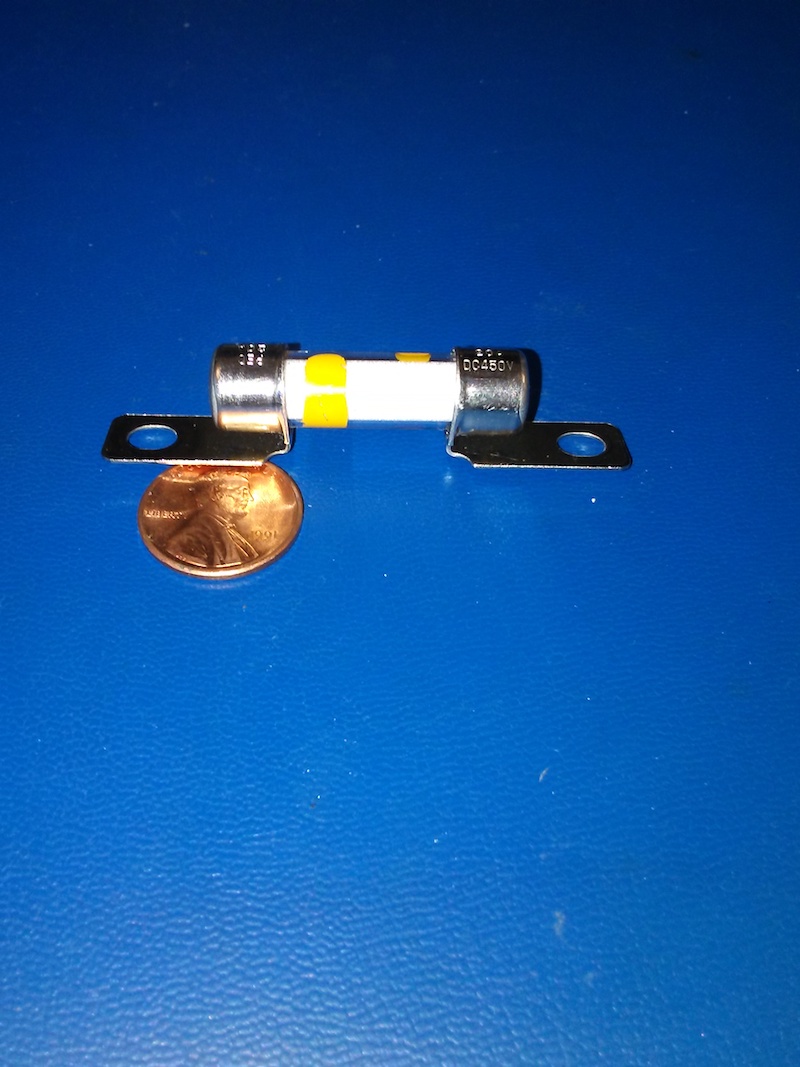

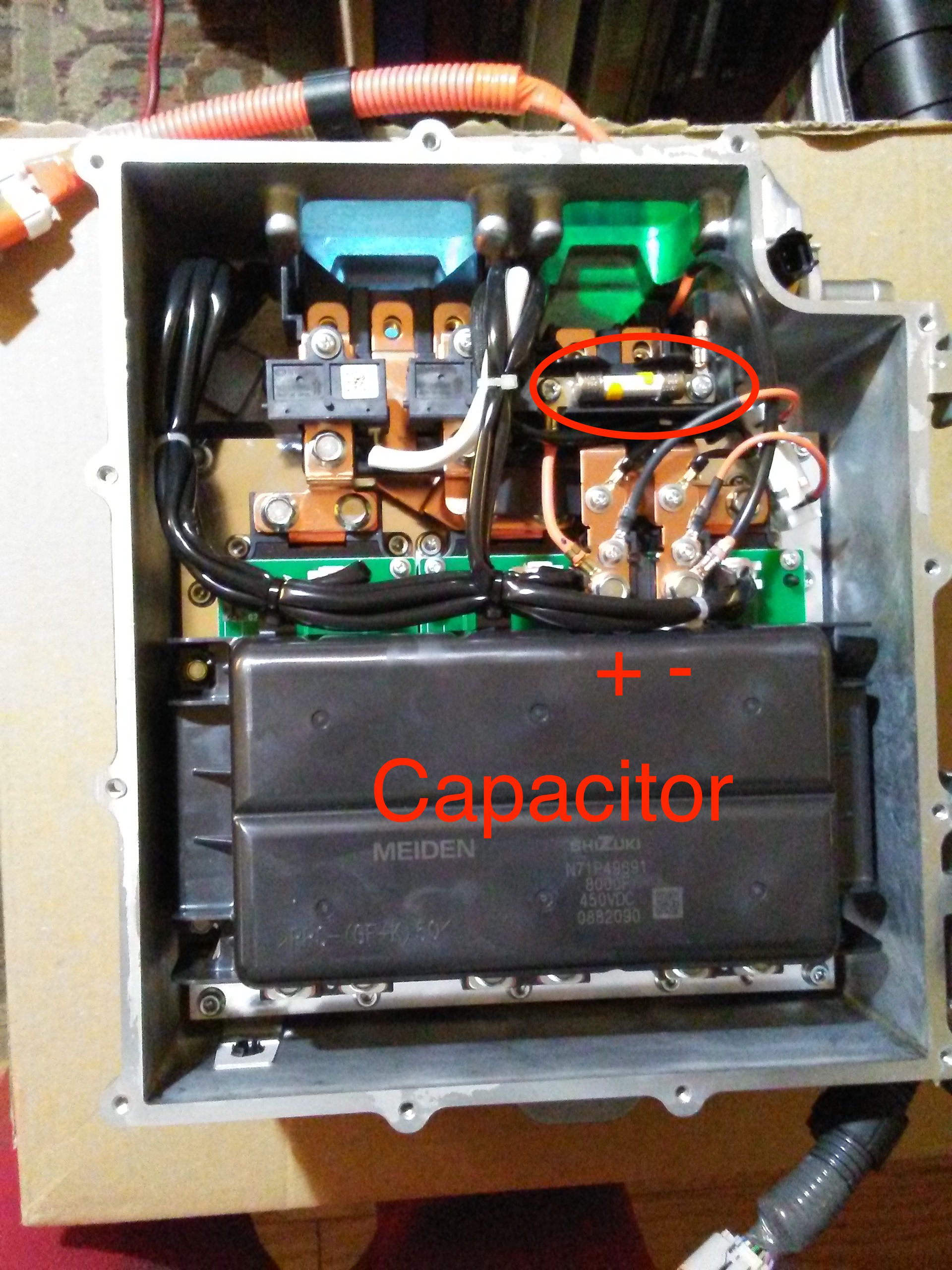

edit: add photo of open MCU to show the fuse. It is behind the small access cover, so no need to remove the cover to replace it.

If the fuse blows during operation of the OBC, then it is very likely that the two snubber capacitors in the HV output section will also be destroyed. This scenario has been reported dozens of times in the past 2 years in the OBC Troubleshooting and Repair thread.

So looking at this another way-- could the fuse have a limited lifetime due to age, wear and tear, etc?

Environmental lifetime factors for fuses are not listed in the datasheets, but i would suggest that automotive electronics has a significant vibration factor for which stationary applications are not usually exposed.

What if the combination of repeated thermal cycling during normal OBC and DCDC operation, plus the mechanical shock and vibration from normal driving on our typically smooth and pothole-free highways over several years, has caused the fuse filament element to develop metal fatigue cracks leading to breakdown?

Could this be the root cause of the numerous OBC failures?

edit: add photo of open MCU to show the fuse. It is behind the small access cover, so no need to remove the cover to replace it.