Finally got the pictures to come up, Did not realize its literal text while editing the post, and picture does not appear until posted.

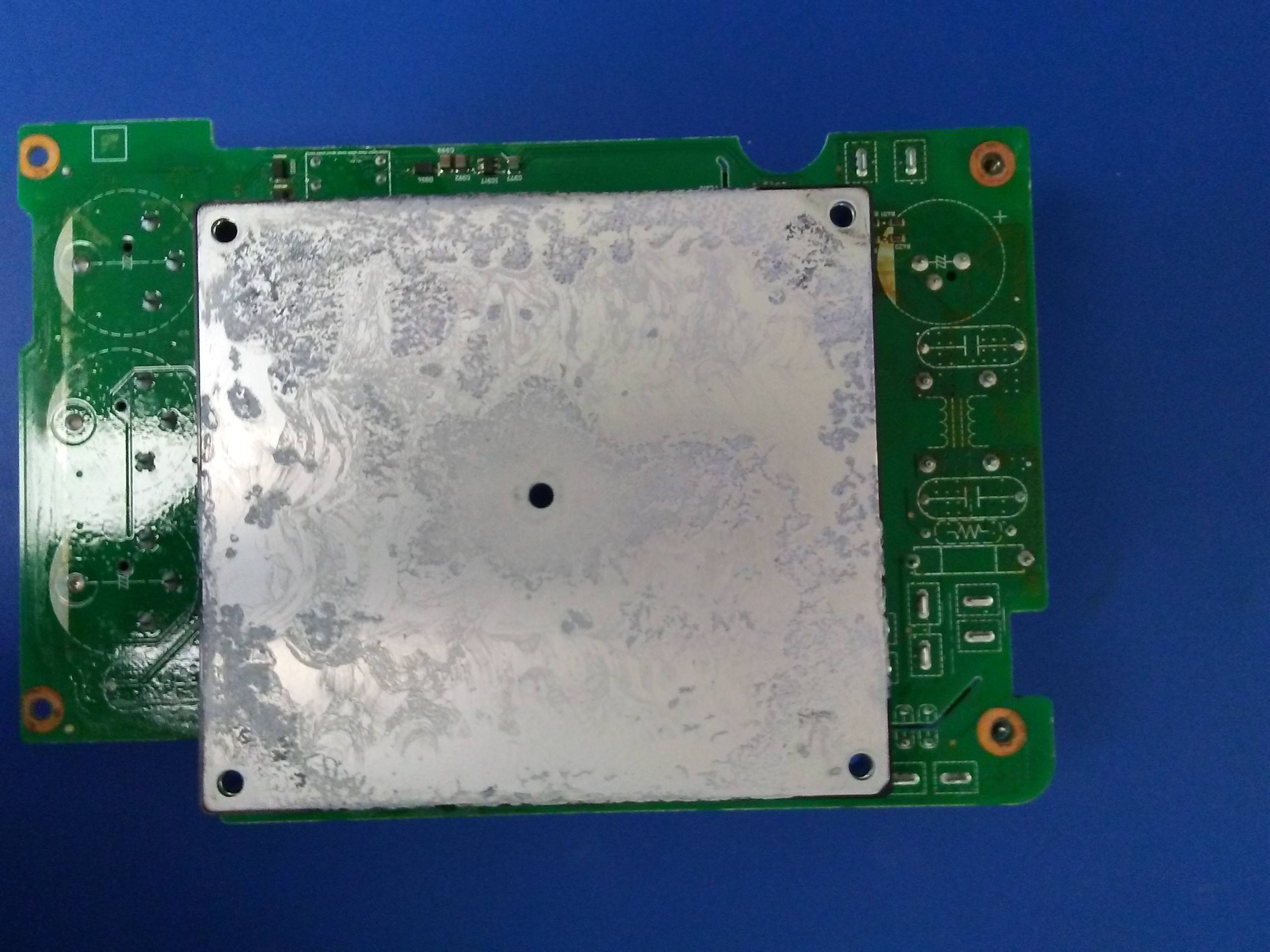

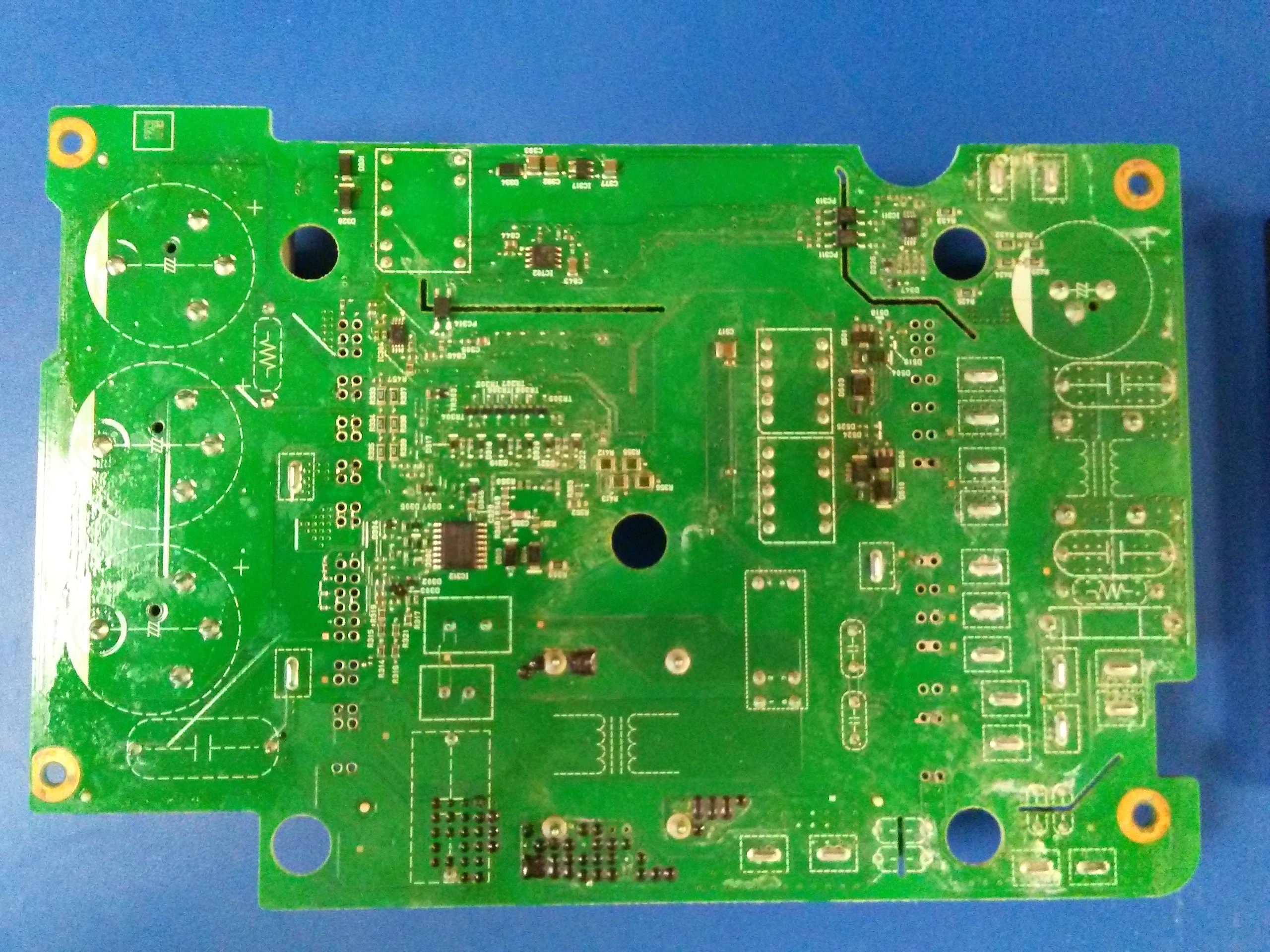

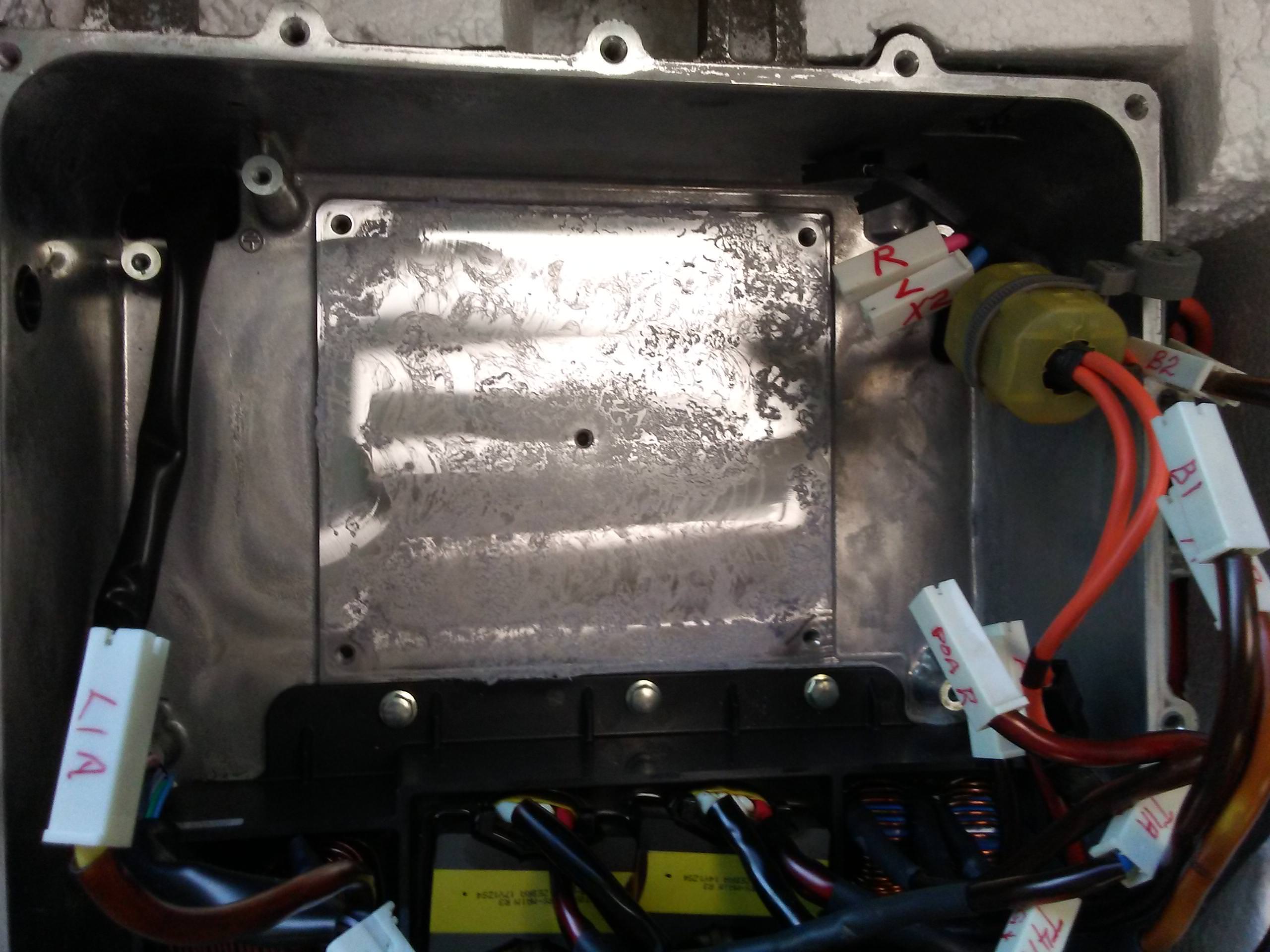

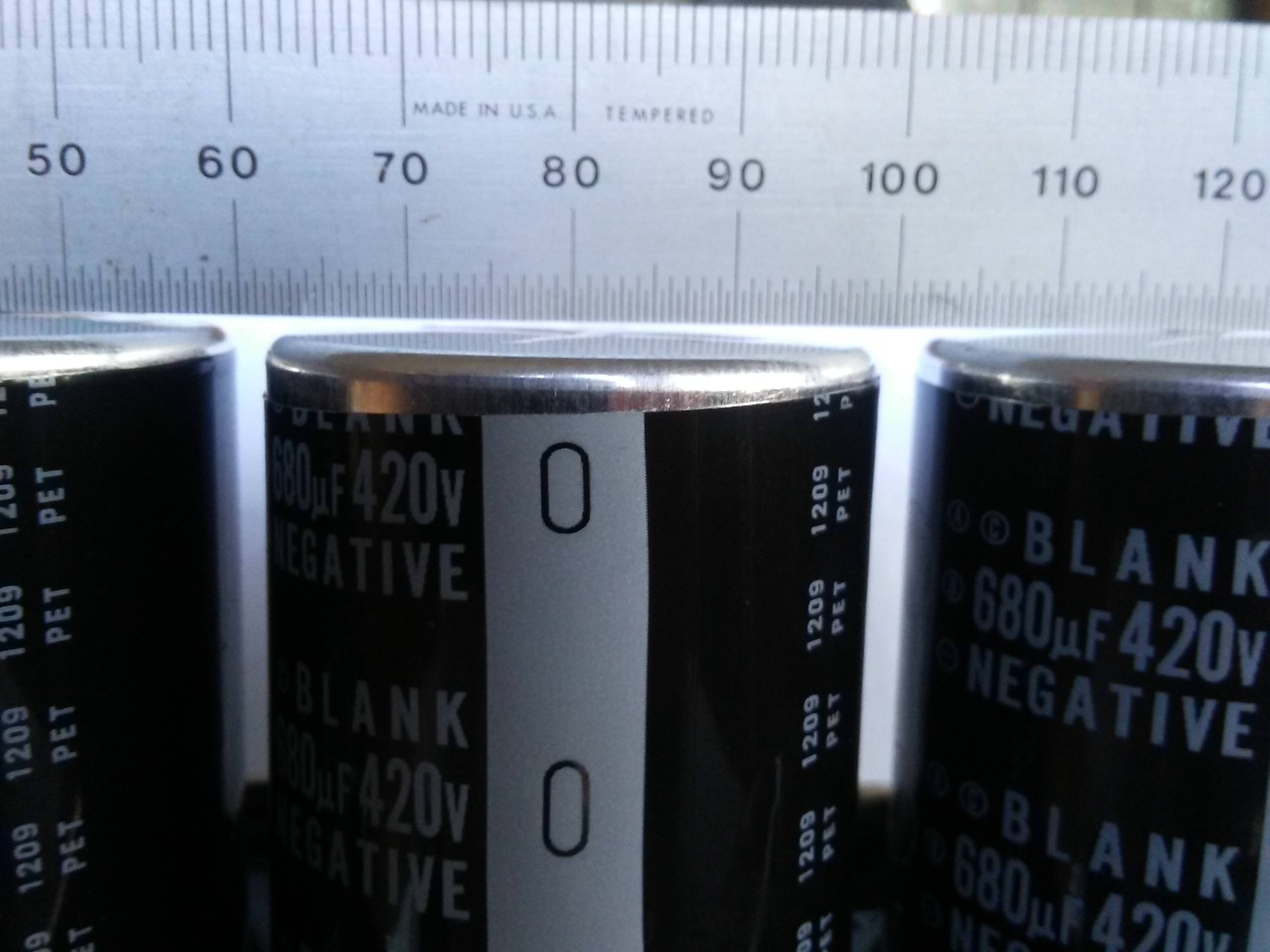

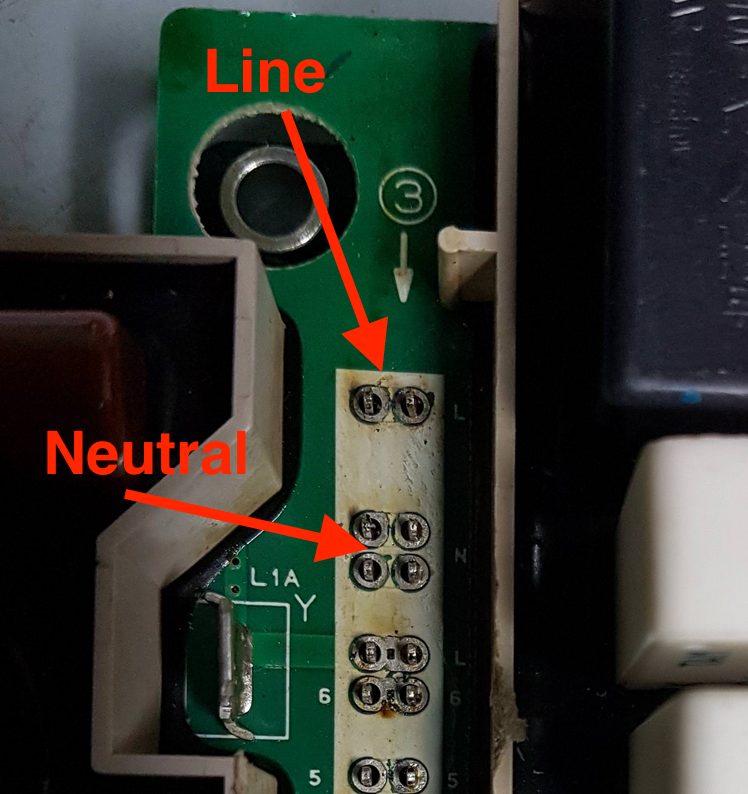

This is the daughter board that emulates the two blue thru hole caps. I think it originally had 4 caps on the board, with spare pads for other unpopulated caps. two of the four caps vaporized along with their tracks and pads. You can see the four square pads at the bottom that attach to pins that go into the Main PCB where C121 and C122 were originally. I left the pins in the main PCB, because so far I have been unable to completely desolder all the pins on the two white strips to be able to remove the power devices and heat sink.

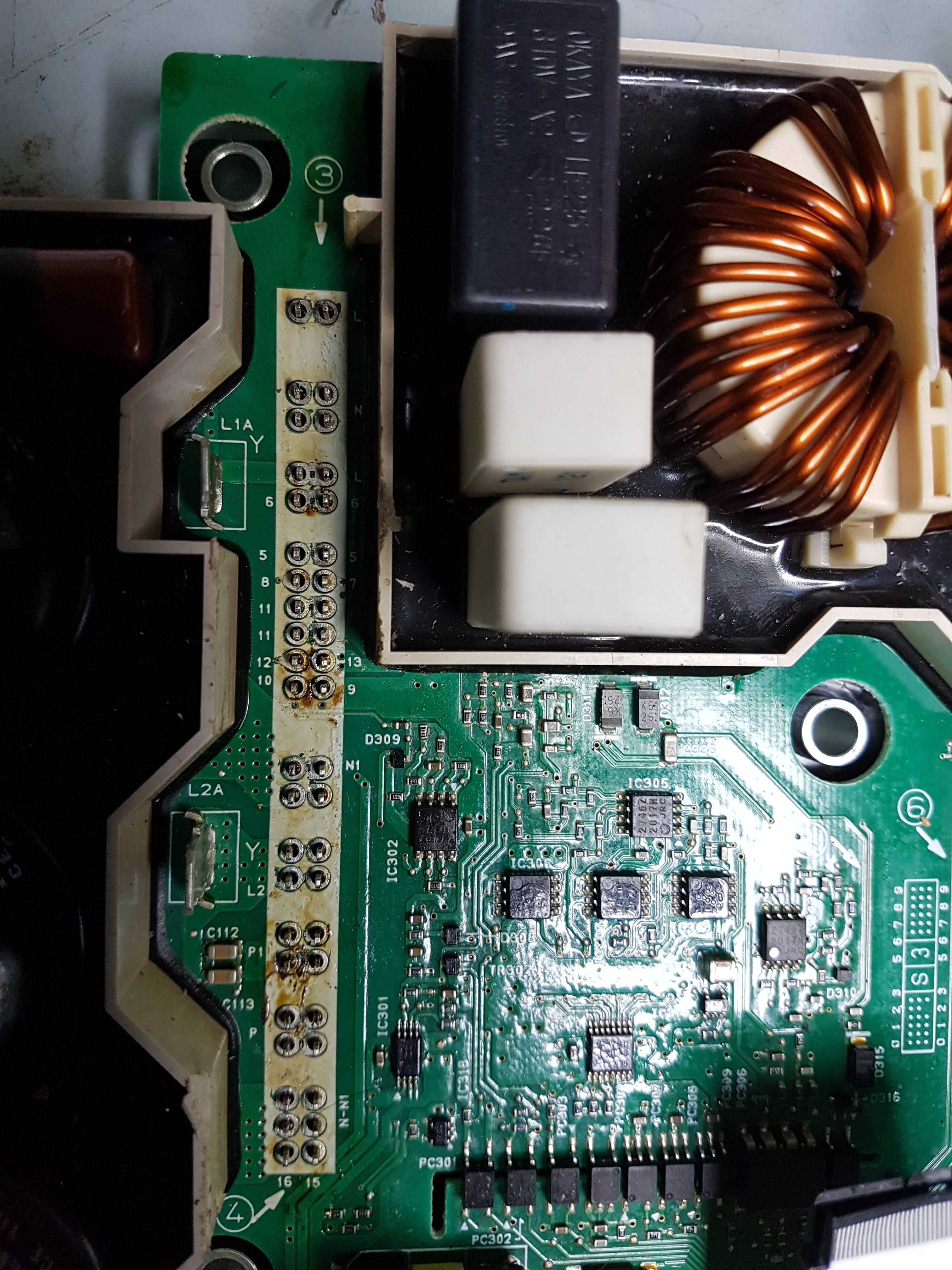

I having a really hard time getting all the solder removed from the holes along the white strips to be able to remove the power devices/heatsink. The solder sucker wasn't working, and I've done multiple sessions going over the pads with solder wick. There are still lots of pins still with small amount of solder, which means I can't leaver or pry without possibly damaging some tracks. I've used up a km of solder wick and will need to do some more shopping before I can do anymore work.

Originally I used an ohm meter across pairs of these pins and found quite a few with zero ohms so I thought I was seeing some shorted power devices. Upon closer look, There are quite a few of these pairs that have tracks between the pair of pads, so this was not a sign of a shorted component, I was just seeing the track between the pads.

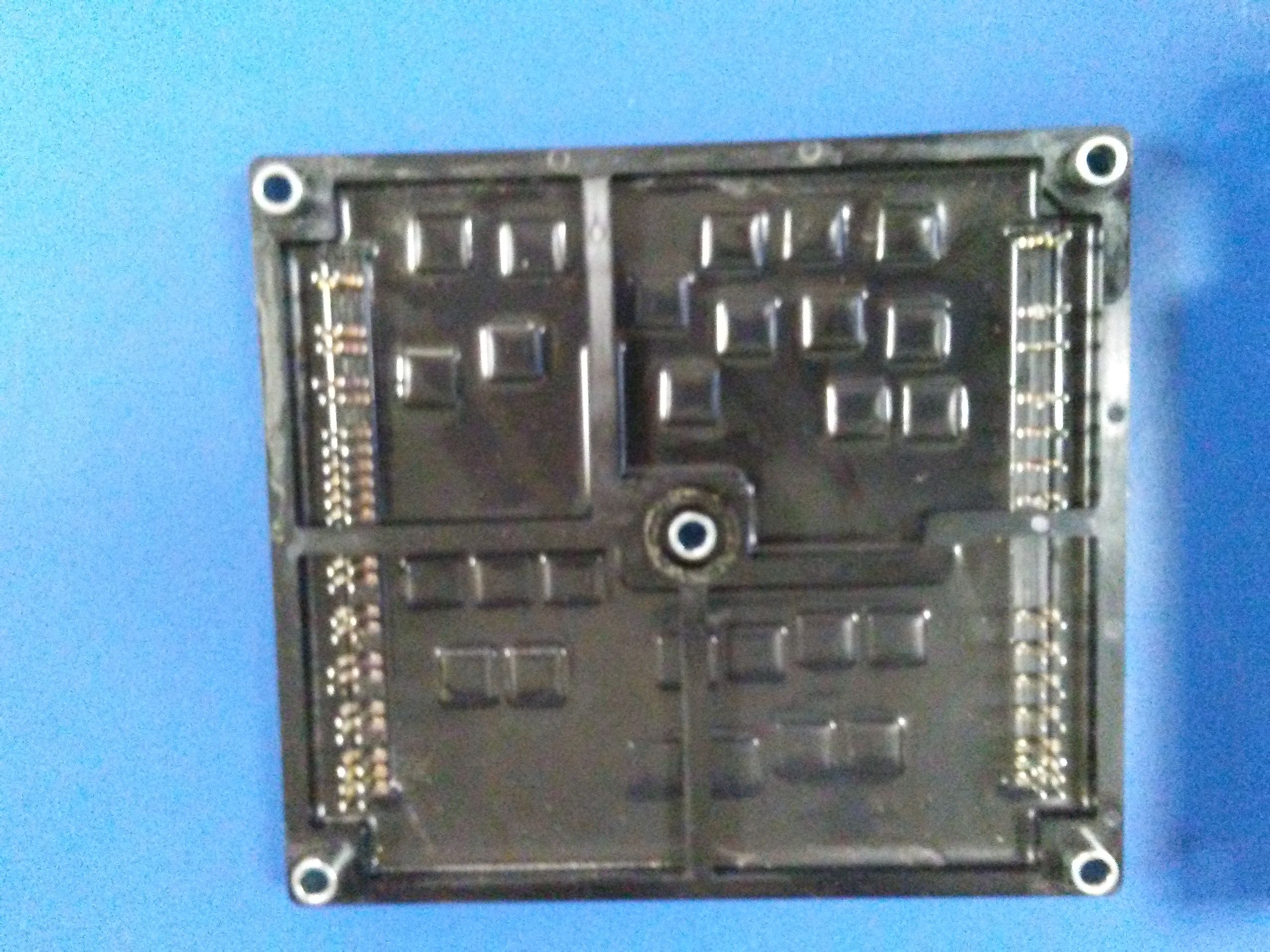

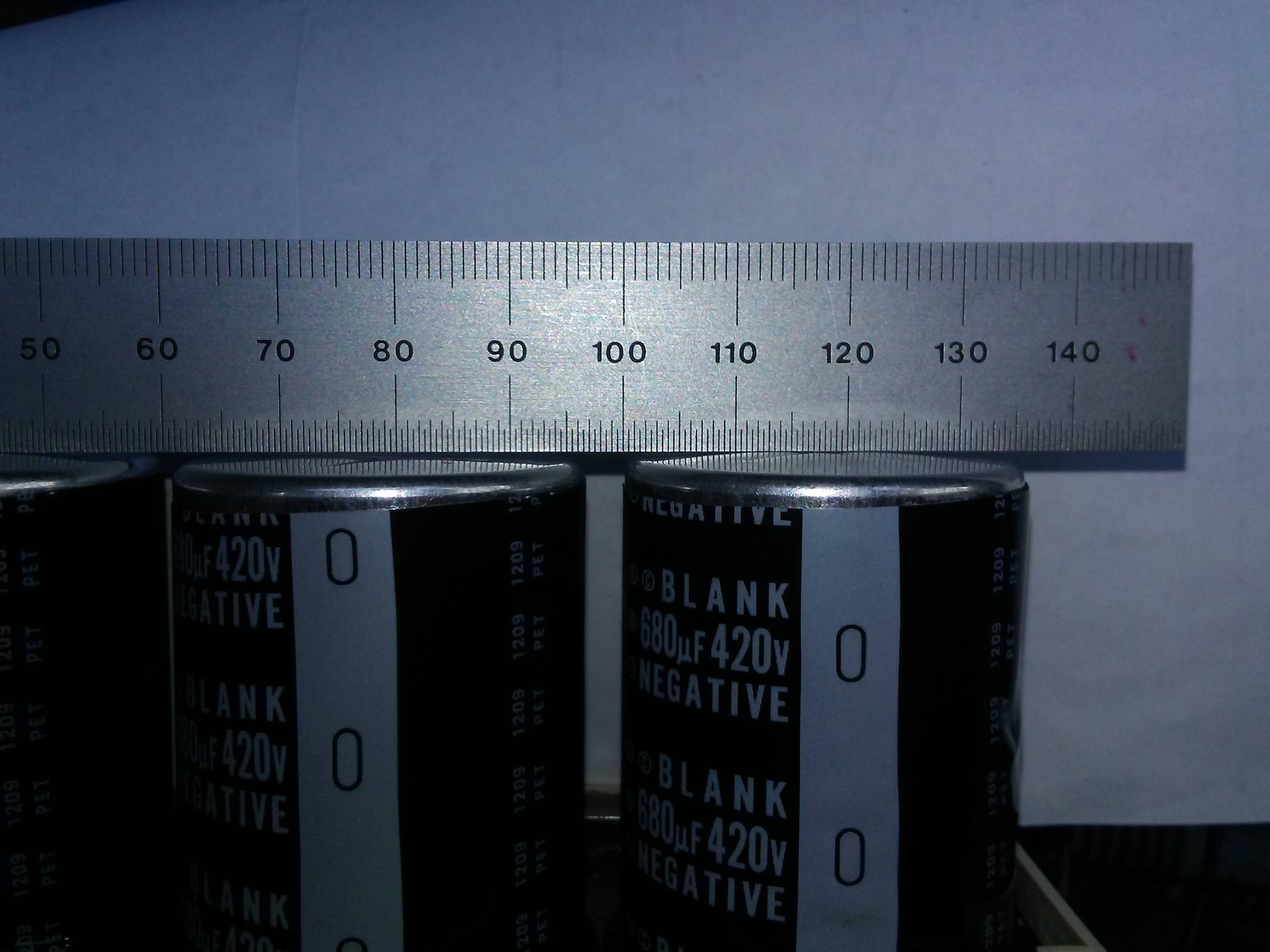

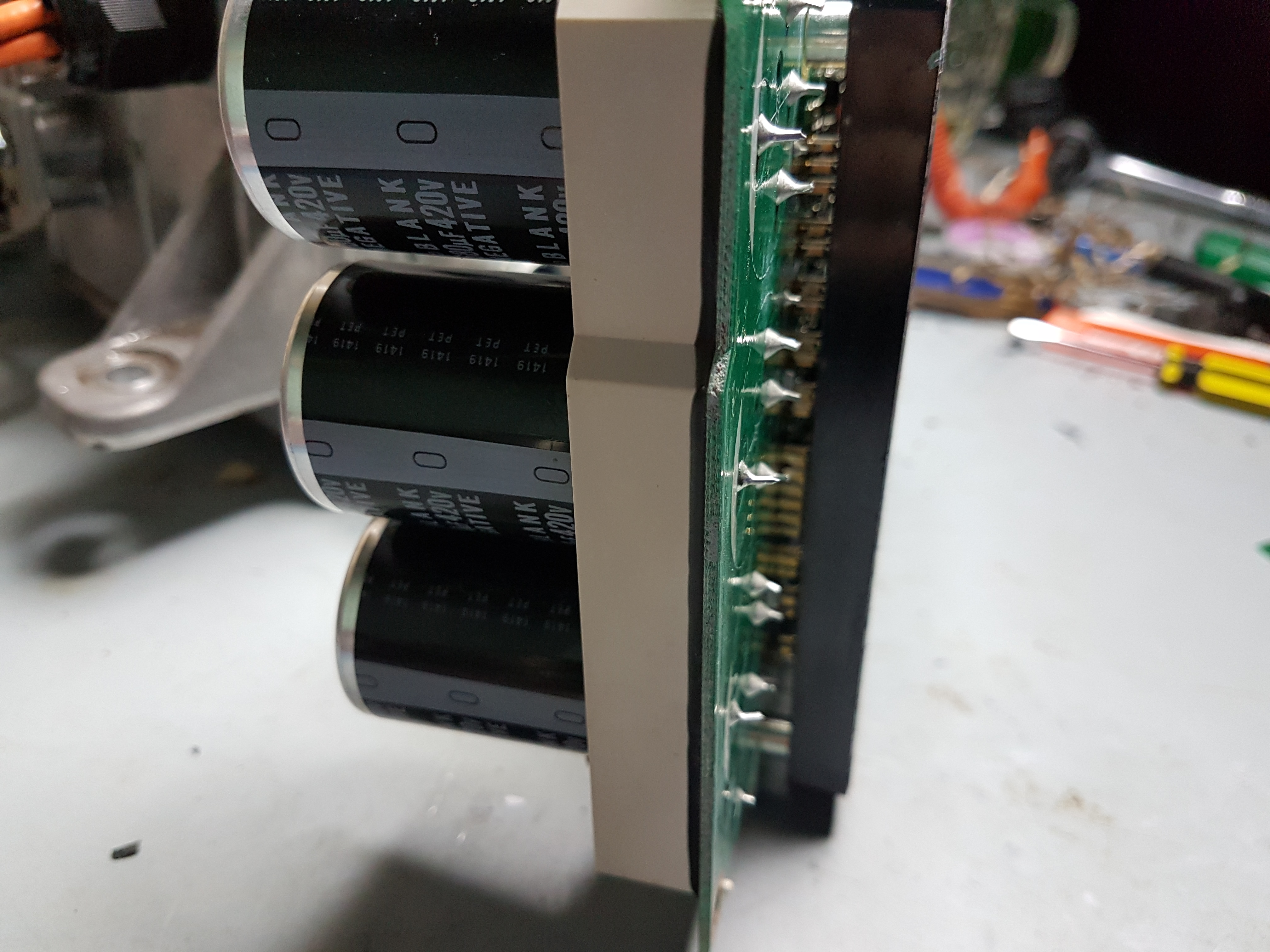

This is a side view of PCB and heatsink. To the left is electrolytic caps in doghouse, to the right, you can see some blurry gold pins/legs between the pcb and the heatsink. Those are the ones I am trying to remove solder from on the white strips on the PCB.